According to a new analysis released today, “The Economic Competitiveness of U.S. Ethanol,” U.S. produced ethanol has been the most economically competitive motor fuel in the world over the past four years. In addition, ethanol has played an important role in  reducing consumer fuel costs. The analysis was conducted by ABF Economics and released by the Renewable Fuels Association (RFA).

reducing consumer fuel costs. The analysis was conducted by ABF Economics and released by the Renewable Fuels Association (RFA).

The analysis reviewed actual wholesale prices paid for ethanol, gasoline and alternative octane source in several U.S. and world markets between 2010-2013. Based on the data, the report concluded, “…U.S.-produced ethanol is an exceptionally competitive additive and fuel source…” and that “…U.S. ethanol has emerged as the lowest cost transportation fuel and octane source in the world over the past several years.”

Commenting on the analysis, RFA President and CEO Bob Dinneen said, “As proven by the recent boom in exports, American-made ethanol has evolved into the most cost competitive transportation fuel and octane source in the world. Through rapid technology adoption and innovation, U.S. producers have proudly earned the distinction of being the global leader and low-cost producer of clean-burning, renewable ethanol.”

Dinneen continued, “Despite the fact that ethanol offers greater consumer choice at a lower cost, entrenched petroleum companies continue to erect barriers that deny access to larger volumes of renewable fuels,” Dinneen continued. “In a truly free market, consumers would always choose a fuel that is produced domestically, is better for the environment and climate, and costs much less than gasoline. Unfortunately, free markets only exist in text books, underscoring the need for monopoly-breaking policies like the Renewable Fuel Standard.”

The ABF Economics study found that even after accounting for transportation costs to the reference markets of Los Angeles, Chicago, and New York, “The ‘spread’ between ethanol and RBOB [gasoline] has averaged 30 to 40 cents per gallon over the past four years in these three key markets and the difference averaged more than 60 cents per gallon in 2012.

As a result of this cost differential, the analysis found “…ethanol blended with RBOB to produce reformulated gasoline at a 10 percent (E10) blend has reduced the cost of motor fuel to consumers.” The analysis found that ethanol’s impact on gas prices goes far beyond the wholesale price spread: “This does not include the additional downward impact ethanol has on gasoline prices as a result of extending supplies and reducing demand for crude oil.”

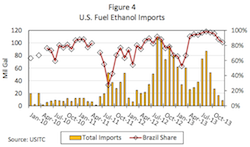

According to the report, “…even with depreciation of the real, U.S. ethanol has been more cost competitive than Brazilian ethanol in key U.S. and world markets over the past several years.” This has particular relevance in the California market, according to the study, because that state’s fuel policies strongly compel fuel suppliers to import Brazilian ethanol in lieu of U.S. ethanol. “Use of Brazilian ethanol in place of U.S. ethanol theoretically raised the price of E10 for California consumers by 8 cents per gallon over the past four years,” the study found.

According to the report, “…even with depreciation of the real, U.S. ethanol has been more cost competitive than Brazilian ethanol in key U.S. and world markets over the past several years.” This has particular relevance in the California market, according to the study, because that state’s fuel policies strongly compel fuel suppliers to import Brazilian ethanol in lieu of U.S. ethanol. “Use of Brazilian ethanol in place of U.S. ethanol theoretically raised the price of E10 for California consumers by 8 cents per gallon over the past four years,” the study found.

In closing, the study indicates that the competitiveness of U.S. ethanol will only improve in the future: “This competitive advantage is expected to increase further, as U.S. ethanol and feedstock producers adopt new technologies and crude oil prices continue to trend higher.”

American Ethanol will be in the spotlight today as driver Austin Dillon will be defending his crown at Eldora Speedway for NASCAR’s Mudsummer Classic World Truck series race in Ohio.

American Ethanol will be in the spotlight today as driver Austin Dillon will be defending his crown at Eldora Speedway for NASCAR’s Mudsummer Classic World Truck series race in Ohio.

contribute to activation of the regional community and improve the regional electricity infrastructure.

contribute to activation of the regional community and improve the regional electricity infrastructure.