If it were up to the Iowa renewable fuels industry, Newt Gingrich would probably be elected the next president of the United States.

If it were up to the Iowa renewable fuels industry, Newt Gingrich would probably be elected the next president of the United States.

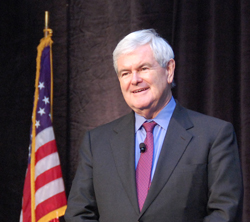

The former speaker of the U.S. House spoke to a full house at the 5th annual Iowa Renewable Fuels Summit in Des Moines on Tuesday. Hitting all the right notes, Gingrich was interrupted several times by applause during his 25 minute address at the summit.

“We need an American energy plan that is designed for good environmental reasons, good economic reasons and good national security reasons,” Gingrich said. “I would rather have the next building boom in Des Moines than in Dubai.”

Gingrich says he is for all types of energy – oil, natural gas, nuclear, wind, solar, renewable fuels and coal – but he thinks food versus fuel is a farce. “The people who talk about food versus fuel are just plain flat wrong,” he said. He said if anyone is to blame for any food shortages, it is the European opposition to using genetically engineered crops.

Probably the biggest applause came when Gingrich gave his opinions on the U.S. EPA. “One of the things we are working on at American Solutions is to develop an Environmental Solutions Agency to replace the Environmental Protection Agency,” he said.

This is a speech well worth a listen.

Listen to or download Newt’s entire speech at IRFA here: Newt Gingrich at Iowa RFA Summit