Researchers at the Massachusetts Institute of Technology (MIT) have found a new way to get more out of harvesting solar energy. This article from the school says they’re using the sun to heat a high-temperature material whose infrared radiation would then be collected by a conventional photovoltaic cell.

Researchers at the Massachusetts Institute of Technology (MIT) have found a new way to get more out of harvesting solar energy. This article from the school says they’re using the sun to heat a high-temperature material whose infrared radiation would then be collected by a conventional photovoltaic cell.

In this case, adding the extra step improves performance, because it makes it possible to take advantage of wavelengths of light that ordinarily go to waste. The process is described in a paper published this week in the journal Nature Nanotechnology, written by graduate student Andrej Lenert, associate professor of mechanical engineering Evelyn Wang, physics professor Marin Soljačić, principal research scientist Ivan Celanović, and three others.

A conventional silicon-based solar cell “doesn’t take advantage of all the photons,” Wang explains. That’s because converting the energy of a photon into electricity requires that the photon’s energy level match that of a characteristic of the photovoltaic (PV) material called a bandgap. Silicon’s bandgap responds to many wavelengths of light, but misses many others.

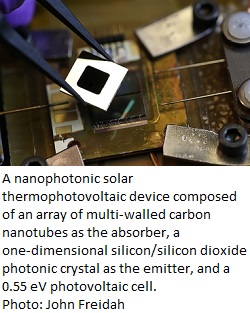

To address that limitation, the team inserted a two-layer absorber-emitter device — made of novel materials including carbon nanotubes and photonic crystals — between the sunlight and the PV cell. This intermediate material collects energy from a broad spectrum of sunlight, heating up in the process. When it heats up, as with a piece of iron that glows red hot, it emits light of a particular wavelength, which in this case is tuned to match the bandgap of the PV cell mounted nearby…

The design of the two-layer absorber-emitter material is key to this improvement. Its outer layer, facing the sunlight, is an array of multiwalled carbon nanotubes, which very efficiently absorbs the light’s energy and turns it to heat. This layer is bonded tightly to a layer of a photonic crystal, which is precisely engineered so that when it is heated by the attached layer of nanotubes, it “glows” with light whose peak intensity is mostly above the bandgap of the adjacent PV, ensuring that most of the energy collected by the absorber is then turned into electricity.

The researchers go on to say this technique will make it easier to store solar energy.