The Board of Directors of the African Development Bank (AfDB) approved an USD 12.7 million African Development Fund partial risk guarantee for the 105 MW Menengai Independent Power Producers project. The global Menengai project will exploit a portion of Kenya’s geothermal potential to provide power to about 500,000 households and 300,000 businesses.

The Board of Directors of the African Development Bank (AfDB) approved an USD 12.7 million African Development Fund partial risk guarantee for the 105 MW Menengai Independent Power Producers project. The global Menengai project will exploit a portion of Kenya’s geothermal potential to provide power to about 500,000 households and 300,000 businesses.- Ground has been broken for a the $10 billion liquefaction export facilities at Cameron LNG in Hackberry, La. The project is being developed by a joint venture formed by Sempra LNG unit, GDF SUEZ S.A., Mitsui & Co., Ltd. and Mitsubishi Corporation, through a related company jointly established with Nippon Yusen Kabushiki Kaisha. The liquefaction project will be comprised of three-train natural gas liquefaction facilities with an export capability of 12 million tonnes per annum of liquefied natural gas (LNG), or approximately 1.7 billion cubic feet per day.

- Unirac, Inc. has been selected by NRG Energy to provide a 6.4 MW DC Roof Mount for installation on the Mandalay Bay Resort and Casino Convention Center in Las Vegas, Nevada.

- Valencia’s Cry-Help Furniture Recycling charity is now being powered by the sun after a donation of solar panels by Zepyor Parseghian and the Solar Servicing Center as part of a four year plan to have 4,500 homes in Santa Clarita, California go green. The nonprofit has been given the green makeover to mark the landmark of 1,000 homes being fitted with solar panels in the Santa Clarita Valley. The installation at the charity is part of an international deal between Zepyor Parseghian’s Solar Servicing Center and the Taiwanese solar company Sung Sun, a Neo Solar Panel group company, and the Santa Clarita Chamber of Commerce.

NRG Energy & MGM Install Rooftop Solar System

NRG Energy, Inc. and MGM Resorts International have completed installation of what they believe is the world’s largest rooftop solar array on a convention center. Covering approximately 20 acres atop the Mandalay Bay Resort and Casino, the 6.4 MW photovoltaic array will produce enough electricity to power the equivalent of 1,000 average sized U.S. homes each year and is the first of its kind on the Las Vegas Strip.

“Together, MGM Resorts and NRG are an excellent example of private sector companies working together to develop innovative technologies that protect our planet’s most precious resources,” said Nevada Senator and Senate Majority Leader Harry Reid. “I applaud MGM and NRG for leading the way for other businesses to embrace environmental best practices, and demonstrating that it’s good for business.”

MGM Resorts and NRG also announced plans to build an additional 2 MW dc photovoltaic array atop a future expansion of the Mandalay Bay Convention Center, scheduled to begin construction later this year.

MGM Resorts and NRG also announced plans to build an additional 2 MW dc photovoltaic array atop a future expansion of the Mandalay Bay Convention Center, scheduled to begin construction later this year.

“Today marks a major milestone for MGM Resorts, NRG and the entire Las Vegas community,” said Jim Murren, Chairman and CEO of MGM Resorts International. “The completion of this solar array demonstrates our steadfast commitment to the principles of environmental responsibility, and the announcement of the second array reinforces that we’re always looking to do more.”

When the addition is completed, the solar project is projected to provide pricing stability and reduce energy draw from the grid during peak times. Through a Power Purchase Agreement (PPA), Mandalay Bay Resort will purchase all the electricity generated by both solar arrays.

Tom Doyle, President and CEO of NRG Renew added, “As one of the largest providers of renewable energy solutions in North America, we’re delighted to be the chosen partner of MGM Resorts to take this giant leap forward and join their longstanding legacy in environmental stewardship. NRG envisions a thriving, sustainable future powered by renewable energy. We look forward to continuing our partnership with MGM in bringing competitively priced, clean energy to Mandalay Bay through the second solar array of this project; further supporting their commitment to reducing energy costs.”

REG Finishes Upgrade at 30 Mil Gallon Biodiesel Plant

Biodiesel giant Renewable Energy Group will be able to crank out high quality biodiesel from a wide variety of raw materials at its Mason City, Iowa plant, thanks to a major upgrade to the 30 million gallon per year facility. This $20 million project has been a year in the making, and the ribbon cutting attracted several state and local government and business leaders.

Biodiesel giant Renewable Energy Group will be able to crank out high quality biodiesel from a wide variety of raw materials at its Mason City, Iowa plant, thanks to a major upgrade to the 30 million gallon per year facility. This $20 million project has been a year in the making, and the ribbon cutting attracted several state and local government and business leaders.

The upgrades enable the Mason City biorefinery to utilize multiple raw materials, such as inedible corn oil, animal fats and greases, in addition to the refined vegetable oils the plant was originally designed to process. The upgrades were completed almost two months ahead of schedule and within budget.

“These upgrades further expand and strengthen our multi-feedstock business model, which allows REG to produce and deliver high-quality biomass-based diesel at an affordable price to growing regional and national markets,” said Daniel J. Oh, REG President and Chief Executive Officer. “We are well-positioned to meet growing demand in Iowa, with its retail incentive for advanced biofuels, and in Minnesota as it increases its use of higher biodiesel blends.”

REG also improved the existing front-end technology at the biorefinery that enables higher yields from free fatty acids in the production process.

“Enhancing the plant’s pretreatment and distillation capabilities will enable us to take a broader spectrum of lower-cost feedstocks and produce a high quality product,” said Brad Albin, REG Vice President, Manufacturing. “The increased feedstock flexibility helps drive greater demand for local feedstock suppliers and keeps more of their products in the Midwest.”

REG bought the Mason City biorefinery a year ago this past summer, reopening it just a few months later. The state and local governments kicked in about $2.5 million in incentives to make it a reality. REG completed a similar upgrade to another 30-million-gallon per year plant just up the road in Albert Lea, Minnesota.

Biodiesel Researcher Flys High with Scholarship

A University of Colorado student who includes biodiesel in her research will be flying high – WAYYYY high – as she is awarded a $10,000 scholarship from the Astronaut Scholarship Foundation. Senior Jeni Sorli picks up the scholarship when former NASA astronaut Bruce McCandless presents the honor on campus on Thursday, Oct. 30.

A University of Colorado student who includes biodiesel in her research will be flying high – WAYYYY high – as she is awarded a $10,000 scholarship from the Astronaut Scholarship Foundation. Senior Jeni Sorli picks up the scholarship when former NASA astronaut Bruce McCandless presents the honor on campus on Thursday, Oct. 30.

Sorli, a chemical engineering major from Billings, Montana, is the recipient of a number of other prestigious awards. She is a Goldwater Scholar, an Engineering Merit Scholar, a Norlin Scholar, a Presidential Scholar and a Conoco Phillips engineering intern.

Sorli currently is involved with the Engineering Honors Program, the CU Chapter of Engineers without Borders and CU Biodiesel. She has been studying renewable fuels, including working in the lab of Professor Alan Weimer researching biomass degasification.

The Astronaut Scholarship is the largest monetary award given in the United States to science and engineering undergraduate students based solely on merit.

Propane – There’s an App for That

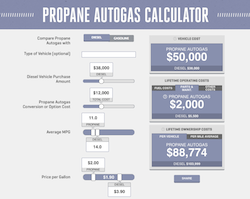

There is a new app for propane. The Propane Education & Research Council (PERC) released a suite of cost calculator tools designed for customers in three of the industry’s fastest-growing markets: agriculture, commercial landscape, and on road fleets. The calculators estimate potential fuel savings and ROI when using propane as compared with conventional fuels such as gasoline and diesel.

There is a new app for propane. The Propane Education & Research Council (PERC) released a suite of cost calculator tools designed for customers in three of the industry’s fastest-growing markets: agriculture, commercial landscape, and on road fleets. The calculators estimate potential fuel savings and ROI when using propane as compared with conventional fuels such as gasoline and diesel.

“One of the main reasons fleets, agribusiness operators or commercial landscapers consider making a switch to an alternative fuel like propane is simple: They want to improve their bottom line,” said Tucker Perkins, PERC’s chief business development officer. “With these new applications, equipment dealers, propane providers, and customers can easily calculate fuel costs with propane specific to their market and operations. And with the online and mobile tools, they can share results on the spot via email.”

The PERC cost calculator series currently includes the Propane Irrigation Engine Calculator, Propane Mower Calculator and Propane Autogas Calculator – all available in multiple different platforms.

BlueFire Renewables to Receive $270M

BlueFire Renewables has received a Letter of Intent from the Export Import Bank of China to provide up to $270 million in debt financing for its bioenergy project located in Fulton, Mississippi. As advanced bioenergy companies struggle with private financing, BlueFire said the the financing is “unprecedented” and significant for the U.S. market.

“This is a significant feat, not just for BlueFire as it also provides a model for the U.S. small business community because it is a strong indication of China’s commitment to support and fund U.S. renewable energy technologies to improve the environment and build a strong foundation for cooperation between China and the U.S. in the field of renewable energy,” said Arnold Klann, CEO of BlueFire Renewables.

According to Klann, BlueFire has been working with China EXIM in response to the China Strategic and Economic Dialogue with the U.S. that encourages U.S./China cooperation in the renewable energy field including financing. Klann believes his company’s technology could be the path to commercialization for many languishing renewable energy projects.

According to Klann, BlueFire has been working with China EXIM in response to the China Strategic and Economic Dialogue with the U.S. that encourages U.S./China cooperation in the renewable energy field including financing. Klann believes his company’s technology could be the path to commercialization for many languishing renewable energy projects.

“There are significant opportunities for replicating the BlueFire Fulton size or larger facilities in China and the U.S. to deal with problematic agricultural and urban waste currently being burned or buried,” added Klann. “Debt financing has been the most difficult part of the financing to obtain for the cellulosic biofuels industry. BlueFire’s business model and relationships with China EXIM will set the standard for future debt financing arrangements and could be the spark that leads to the more beneficial use of cellulosic wastes in the biofuels industry in the U.S. and China. We are cracking the code when it comes to striking a win-win business deal for China, the U.S. and energy consumers.”

The Letter of Intent continues the international collaboration between U.S. and China initiated by BlueFire. The companies will continue to work together to complete the standard due diligence procedures of the China EXIM bank and meet all credit criteria and condition precedent to reach definitive agreements in order to complete the financing as soon as possible. Once completed, China Three Gorges Corporation and its U.S. subcontractors will begin construction of the Fulton Project.

Ansell Installs Biomass Boiler to Reduce Energy Costs

The Ansell factory complex in Biyagama, Sri Lanka has installed its second biomass boiler as part of company initiatives to be greener. The new boiler has a capacity of 12.5MW and will be the largest hot water boiler in Sri Lanka. Ansell Lanka already has a 10.5MW boiler installed at its premises, which reduced CO2 emissions by 11,000 MT per annum. From 2004 to 2012, CO2 emissions have been reduced by 36 percent across all of Ansell’s manufacturing facilities, with the global CO2 emission rate from 2013 to 2014 alone reduced by 6 percent. The company anticipates the reduction of a further 14,000 MT of CO2 emissions annually as furnace oil consumption will now be reduced to the bare minimum.

“This project represents another step forward in Ansell’s business strategy to conducting business ethically, transparently, and in ways that produce social, environmental, and economic benefits for communities around the world,” said Steve Genzer, senior vice president of global operations at Ansell. “We would like to thank the government of Sri Lanka for its continued support, and the more than 4,000 Ansell employees who are the driving force of implementing these green programs.”

“This project represents another step forward in Ansell’s business strategy to conducting business ethically, transparently, and in ways that produce social, environmental, and economic benefits for communities around the world,” said Steve Genzer, senior vice president of global operations at Ansell. “We would like to thank the government of Sri Lanka for its continued support, and the more than 4,000 Ansell employees who are the driving force of implementing these green programs.”

The announcement is part of the company’s Green Productivity program, focused on energy management, and implemented within manufacturing operations across Ansell. Energy management at Ansell focuses on achieving the most efficient and effective use of energy and simultaneously reducing greenhouse gas emissions. Programs that have been implemented include the installation of equipment to recover energy from flue gas emitted from boiler chimneys as an energy source to heat water, the installation of energy efficient equipment to provide chilled water for manufacturing site cooling systems and the conversion of fossil fuels to renewable energy sources.

“While the forward progress made in the last 10 years has been incredible, this is only the tip of the iceberg in how Ansell will be doing business differently in the years to come,” added Genzer. “Ansell is committed to a number of sustainable and practical initiatives that are designed to make a positive and lasting contribution to the markets it serves and the community in general.”

Study: Leasing Ups Interest in Residential Solar

A national poll by EnviroMedia finds that a large majority of Americans are definitely or somewhat interested in new solar leasing programs offering installation for little or no money down and a low monthly fee.

“It’s no surprise we found 70 percent of Americans perceived ‘cost’ was a barrier to installing solar panels,” said EnviroMedia president and behavior change expert Kevin Tuerff. “Consumers are probably unaware of the plummeting cost of solar power, and most have never heard of solar leasing.”

“It’s no surprise we found 70 percent of Americans perceived ‘cost’ was a barrier to installing solar panels,” said EnviroMedia president and behavior change expert Kevin Tuerff. “Consumers are probably unaware of the plummeting cost of solar power, and most have never heard of solar leasing.”

The new poll finds 48 percent of American homeowners say they have not considered adding solar panels to their home to offset some of their electricity use. However interest in a solar option spiked when respondents were educated about the benefits of a solar leasing program. About 67 percent said that they were very or somewhat interested in such a program.

The poll also found that only 9 percent of respondents said they currently participate in a renewable energy or green power option with their electricity provider. But 69 percent said they might be interested.

“Americans need basic education about where their electricity comes from and how clean energy works,” added Tuerff. “Unfortunately, only one-third of Americans said they definitely know the fuel source of their electricity, so we’ve got a ways to go.”

BioEnergy Bytes

Governor Cuomo has announced the New York Green Bank’s first tranche of deals, totaling $800 million in clean energy investments across the state. Rather than providing grants to stimulate clean energy investment, green banks use attractive interest rates and other incentives to leverage money from the private sector. The NY Green Bank’s initial investment of $200 million galvanized $600 million in investment from prominent financial institutions. The first seven transactions, which will close over the next few months, finance a wide range of low-carbon, clean energy projects, including solar, energy equipment and energy efficiency.

Governor Cuomo has announced the New York Green Bank’s first tranche of deals, totaling $800 million in clean energy investments across the state. Rather than providing grants to stimulate clean energy investment, green banks use attractive interest rates and other incentives to leverage money from the private sector. The NY Green Bank’s initial investment of $200 million galvanized $600 million in investment from prominent financial institutions. The first seven transactions, which will close over the next few months, finance a wide range of low-carbon, clean energy projects, including solar, energy equipment and energy efficiency.- ACI’s Global Geothermal Energy Summit will take place in Reykjavik, Iceland February 18-19, 2015. Through case study presentations, keynotes, panel discussions and interactive sessions, this two day summit will take a deep dive into: global geothermal energy policy update and industry outlook; meeting the latest government & environmental policy and compliance requirements to ensure project approvals; case studies of latest technological advances to ensure cost reduction and project success for your geothermal projects; financing geothermal projects and more.

- Exosun and Daetwyler Clean Energy have strategically partnered to provide a full range of best-in-class mounting and tracking solutions. Each company will provide the full range of mounting and tracking products.

- Solar Power Rocks has released its 2015 State Solar Power Rankings report. The report contains ratings of all 50 states and the District of Columbia based on twelve key criteria leading to strong financial results for homeowners interested in installing solar panels. State summaries include links to pages with detailed discussions of policy, incentives and rules that affect each state’s residential solar power prospects.

No Doubt RFS Uncertainty Impacts Local Communities

Our latest ZimmPoll asked the question, “Has the uncertainty for the RFS caused by the EPA hurt your community?”

Our latest ZimmPoll asked the question, “Has the uncertainty for the RFS caused by the EPA hurt your community?”

No doubt the uncertainty for the Renewable Fuel Standard (RFS) caused by the EPA has hurt many of our communities. This unpredictability has been around over a year and has left many wondering what the final renewable fuel volumes will be. I am sure the uncertainty has impacted our lives more then many even are aware.

Here are the poll results:

- Yes, lost local business/jobs – 73%

- No, no impact – 27%

- Don’t know – 0%

Our new ZimmPoll is now live and asks the question, What should US do about WTO COOL ruling?

The industry has reacted to the World Trade Organization (WTO) decision against the United States on the Country of Origin Labeling (COOL) law since the announcement was made earlier this week. Some feel the issue can be handled by USDA, others feel Congress should take charge. Or are there are other options?