Martifer Solar Canada, a subsidiary of Martifer Solar SA, and Triumph, Inc. have entered into a strategic partnership to serve the growing demand for solar photovoltaic (PV) in the Canadian market. The partnership will be called Martifer Solar Triumph and will add unique value to the market based on the companies´ shared complementary competencies. Martifer Solar Triumph will be headquartered in Toronto and focused on the market in Ontario, which has strong incentives for solar photovoltaic installations. The company will be an active player in solar Development, EPC and O&M Service of rooftop and ground-mounted PV projects.

Martifer Solar Canada, a subsidiary of Martifer Solar SA, and Triumph, Inc. have entered into a strategic partnership to serve the growing demand for solar photovoltaic (PV) in the Canadian market. The partnership will be called Martifer Solar Triumph and will add unique value to the market based on the companies´ shared complementary competencies. Martifer Solar Triumph will be headquartered in Toronto and focused on the market in Ontario, which has strong incentives for solar photovoltaic installations. The company will be an active player in solar Development, EPC and O&M Service of rooftop and ground-mounted PV projects.- Alstom has signed a new contract with Vartinoja 1 Ky to supply a wind farm located in Siikajoki, Northern Finland. The turnkey contract is worth €35 million and covers the engineering, manufacture, delivery and commissioning of 9 ECO 122 wind turbines of the 2.7 MW capacity model, ideal for medium and low wind sites. Together they will generate a maximum capacity of 24 MW. The contract also includes 12 years of operation and maintenance services.

- The European Union will finance Rwanda’s clean energy projects to develop sustainable sources of energy to maintain the country’s rapid growth, but protect the environment, according to new agreements. On September 23, 2014 Rwanda’s President Paul Kagame signed the support agreement in New York with Jose Manuel Durao Barroso, President of the European Commission, at the sideline of the Climate Change Summit. The EU announced that Rwanda will benefit from its €3.3 billion ($4b) financing to clean energy projects along with five other African nations. About €2b will be disbursed to five African countries, including Rwanda, Cabo Verde, Cote d’Ivoire, Liberia, and Togo.

Researchers Discover Cellulose Making Enzyme Structure

Researchers from Purdue University have discovered the structure of the enzyme that makes cellulose. They believe this finding could lead to easier ways of breaking down plant materials to make biofuels and other products and materials. In addition the researchers say the findings provide a more detailed glimpse of the complicated process by which cellulose is produced. Cellulose is the foundation of the plant cell wall and can be converted to bioproducts such as biofuels and biochemicals. The research findings were published in The Plant Cell.

“Despite the abundance of cellulose, the nitty-gritty of how it is made is still a mystery,” said Nicholas Carpita, professor of plant biology. “Now we’re getting down to the molecular structure of the individual enzyme proteins that synthesize cellulose.”

Carpita explains that cellulose is composed of several dozen strands of glucose sugars linked together in a cablelike structure and condensed into a crystal. The rigidity of cellulose allows plants to stand upright and lends wood its strength. “Pound for pound, cellulose is stronger than steel,” said Carpita.

Carpita explains that cellulose is composed of several dozen strands of glucose sugars linked together in a cablelike structure and condensed into a crystal. The rigidity of cellulose allows plants to stand upright and lends wood its strength. “Pound for pound, cellulose is stronger than steel,” said Carpita.

A large protein complex synthesizes cellulose at the surface of the plant cell. The basic unit of this complex is an enzyme known as cellulose synthase. The protein complex contains up to 36 of these enzymes, each of which has a region known as the catalytic domain, the site where single sugars are added to an ever-lengthening strand of glucose that will be fixed in the plant cell wall as one of the strands in the cellulose “cable.”

Carpita and a team of researchers used X-ray scattering to show that cellulose synthase is an elongated molecule with two regions – the catalytic domain and a smaller region that couples with another cellulose synthase enzyme to form a dimer, two molecules that are stuck together. These dimers are the fundamental building blocks of the much larger protein complex that produces cellulose.

“Determining the shape of cellulose synthase and how it fits together into the protein complex represents a significant advance in understanding how these plant enzymes work,” Carpita said.Read More

Dark Horse Brewing Brews With Solar

Patriot Solar Group, Contractors Building Supply, The Green Brewery Project, and The Dark Horse Brewing Company have created the first solar power-driven brewery on the east coast. The 40 kilowatt, 140 panel system has helped generate solar energy and aid in the formation of the famous Dark Horse growler we all know and love.

Patriot Solar Group, Contractors Building Supply, The Green Brewery Project, and The Dark Horse Brewing Company have created the first solar power-driven brewery on the east coast. The 40 kilowatt, 140 panel system has helped generate solar energy and aid in the formation of the famous Dark Horse growler we all know and love.

The Green Breweries Project, whose research originated at the University of Michigan, is focused on offering creativity with energy systems to help craft breweries enhance their sustainability. Even with a considerably lower rate of emissions, Green Breweries are becoming increasingly predominant and are making the exchange to a further domestic market.

Dark Horse purchased 140 Michigan-assembled solar panels as well as mounting systems supplied by Patriot Solar Group. This off-grid system allows the brewery to manage their energy demands and monitor them closely with affluence as well as ease. According to Patriot Solar Group, the fixed standing metal roof mount systems are durable and can withstand brutal wind speeds but also offer minimal maintenance as well as low cost.

Badger State Ethanol Hosts Foreign Ag Guests

Badger State Ethanol in Monroe, Wisconsin had the honor of hosting the 2014 Foreign Agricultural Attaché Tour this week.

Badger State Ethanol in Monroe, Wisconsin had the honor of hosting the 2014 Foreign Agricultural Attaché Tour this week.

The group is part of the USDA’s Foreign Agriculture Service and is made up of 26 representatives from more than a dozen countries including Japan, Korea, Malaysia, Spain, Switzerland, Finland, France, Angola, Canada, Germany, Mexico, Philippines, New Zealand, Nigeria, Ghana, United Kingdom of Great Britain and Northern Ireland.

The Wisconsin Department of Agriculture, Trade and Consumer Protection are playing host to the group for the week to educate them about the quality and diversity of Wisconsin agriculture. The group visited Badger State Ethanol on Monday to take a tour of the facility and learn about the importance of biofuels to the world economy.

Forecast for Next Season = Buying & Planting Less

Our latest ZimmPoll asked the question, “How will low crop prices impact next year?”

Our latest ZimmPoll asked the question, “How will low crop prices impact next year?”

Corn and soybean prices have dropped dramatically this year with record crops but the question is how much will that impact plans for next season. Will farmers plant less, buy less, or just hope prices will go back up next year? It looks like most feel farmers will be buying less and therefore equipment sales will be down. But overall we can expect to see fewer of all things.

Here are the poll results:

- Lower planted acreage – 28%

- Lower equipment sales – 38%

- Less use of new traits – 10%

- No impact – 19%

- Other – 5%

Our new ZimmPoll is now live and asks the question, When do you think medicinal marijuana will become a major cash crop?

More and more states are legalizing the use of medicinal marijuana and a few are even legalizing it completely. What does this mean for agriculture? Are we looking at the next major cash crop or will this trend fade?

Maverick Unveils Small-Scale Plant for Biodiesel Ingredient

A North Carolina company has unveiled an affordable, small scale modular plant for the biodiesel ingredient methanol. Maverick Synfuels says its Maverick Oasis system is the first small-scale, modular methane-to-methanol production plant that can be co-located at the methane source.

A North Carolina company has unveiled an affordable, small scale modular plant for the biodiesel ingredient methanol. Maverick Synfuels says its Maverick Oasis system is the first small-scale, modular methane-to-methanol production plant that can be co-located at the methane source.

The Maverick Oasis factory-built Gas-to-Liquids (GTL) methanol plants are modular, and can be rapidly deployed onsite to produce thousands of gallons per day of ultra-clean methanol from natural gas or methane-rich waste gas. The plants are designed to be low-cost, highly efficient facilities optimized to generate an attractive project rate of return. Each Oasis modular facility comes equipped with performance guarantees based on the designed methanol output rating.

The Maverick Oasis system uses proprietary technology to convert a variety of methane-containing feedstocks; biogas, natural gas (including stranded gas and flare gas), coal bed methane, and landfill gas, into AA grade methanol that meets ASTM D1152 specifications.

With a footprint of just 5,000 square feet, each plant is modular so that it can be shipped to the operational location, where it is assembled by a team of Maverick engineers and integrated with the local infrastructure.

The company goes on the say that each modular facility can crank out 3,000 and 10,000 gallons of methanol per day. The Oasis system is feedstock flexible, able to be used on dairy farms, waste water treatment plants, and other facilities that use anaerobic digesters to process animal, food, and other organic waste, to make methanol. It can even be used on oil and gas fields to produce the important biodiesel ingredient.

Schott, Algatech Ink Research Deal for Biodiesel Feedstock

An international glass maker and a biotechnology company specializing in algae production have signed a deal that could improve cultivation of the biodiesel feedstock algae. Schott AG and Algatechnologies Ltd. (Algatech), studied new DURAN® glass tubes that significantly improved cultivation efficiency in the yields of Algatech’s AstaPure® natural astaxanthin and plan to present their findings at the Algae Biomass Summit, at the end of this month in San Diego, Calif.

An international glass maker and a biotechnology company specializing in algae production have signed a deal that could improve cultivation of the biodiesel feedstock algae. Schott AG and Algatechnologies Ltd. (Algatech), studied new DURAN® glass tubes that significantly improved cultivation efficiency in the yields of Algatech’s AstaPure® natural astaxanthin and plan to present their findings at the Algae Biomass Summit, at the end of this month in San Diego, Calif.

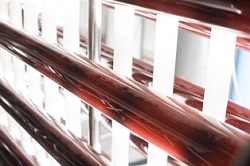

Algatech sought to optimize cultivation of AstaPure, a premium natural antioxidant known as astaxanthin, as part of its goal to double production capacity. SCHOTT partnered with Algatech in 2013 to produce 16 kilometers—nearly 10 miles—of thin-walled DURAN glass tubes for testing in Algatech’s photobioreactor (PBR) production systems at its array in Israel.

SCHOTT reduced the wall thickness of the special DURAN tubes while maintaining their strength and stability. The thinner walls facilitate higher volume and increased sun exposure of the microalgae. The use of DURAN tubes resulted in an increase in algae production efficiency and higher yields of AstaPure astaxanthin.

“From energy to medicine, cosmetics to nutraceuticals, many different industries rely on algae,” said Raz Rashelbach, R&D manager at Algatech. “The success of the thin-walled DURAN tubing has helped increase the AstaPure production efficiency on a small scale that can now be replicated on a much larger scale.”

“Further testing and development of new products in partnership with Algatech will allow us to continue finding new ways and methods to improve algae production,” added Nikolaos Katsikis, Director, Business Development at SCHOTT Tubing.

The agreement signed is expected to expand the two companies’ joint cooperation on new microalgae-based products.

DOE Supports Taller Wind Turbine Tower Development

The U.S. Department of Energy (DOE) has awarded $2 million to support the development of technologies to harness stronger winds available at higher heights. The goal is to increase the amount of wind energy produced. The projects will take place in Iowa and Massachusetts and are aimed at reducing the cost of wind energy as well as expand the areas where wind energy can be successfully harnessed.

In the northeastern, southeastern, and western United States, winds near the ground are often slower and more turbulent, reducing the amount of electricity installed turbines can generate. Taller wind turbines capture the stronger, more consistent winds available at elevated heights, increasing the number of potential locations where wind farms can supply cost-effective power to American businesses and homeowners. While wind turbines installed in 2013 had an average height of 260 feet, the projects announced today will support new design and manufacturing techniques to produce towers nearly 400 feet tall.

In the northeastern, southeastern, and western United States, winds near the ground are often slower and more turbulent, reducing the amount of electricity installed turbines can generate. Taller wind turbines capture the stronger, more consistent winds available at elevated heights, increasing the number of potential locations where wind farms can supply cost-effective power to American businesses and homeowners. While wind turbines installed in 2013 had an average height of 260 feet, the projects announced today will support new design and manufacturing techniques to produce towers nearly 400 feet tall.

Keystone Towers of Boston, Massachusetts will utilize its grant dollars to implement an on-site spiral welding system that will enable turbine towers to be produced directly at or near the installation site, freeing projects of transportation constraints that often limit turbine height. Adapted from an in-field welding process used by the pipe manufacturing industry, Keystone’s spiral welding technique can be scaled up to produce large diameter steel towers that they report will be 40 percent lighter than standard turbine towers, which could lower the cost of energy by 10 percent.

The second grantee, Iowa State University, will develop a hexagonal-shaped tower that combines high-strength concrete with pre-stressed steel reinforcements to assemble individual tower modules and wall segments that can be easily transported and joined together on-site. Due to the modular design, thicker towers capable of supporting turbines at increased heights can be produced at a reduced cost.

Enviro Groups React to Prez Obama’s Climate Speech

“Yes this is hard, but there should be no question that the United States of America is stepping up to the plate. We recognize our role in creating this problem, we embrace our responsibility to combat it. We will do our part,” said U.S. President Barack Obama during the 2014 United Nations Climate Summit that is taking place this week in New York.

During his speech he pledged to put forth a proposal to continue combating climate change beyond 2020 as well as committed to addressing the serious and growing impacts of climate change that the poorest and most vulnerable around the world are already facing. In addition, he took responsibility for America’s role in climate change.

“As I sat in the audience today, I heard President Obama demonstrate the kind of climate leadership the world needs. He made it clear the U.S. is serious about fighting climate change through major cuts to our carbon pollution and other greenhouse gas emissions,” said Frances Beinecke, president of the Natural Resources Defense Council (NRCD) after the speech. “He promised to help communities around the world become more resilient and speed their development of clean energy. And he challenged other nations to step up their climate actions by promising a commitment to our own. This was a message of hope — hope that together we can head off the worst damages from climate change and leave our children a healthier world.”

Jennifer Morgan, director, Climate and Energy Programs for the World Resources Institute welcomed the President Obama’s clear focus and personal commitment. “I am encouraged by President Obama’s promise to put forth an ambitious post-2020 climate commitment early next year. Strong signals that the United States is decarbonizing its economy will set the stage for a successful outcome at the climate negotiations next year. As growing evidence shows, investing in a low-carbon economy creates jobs, reduces air pollution and improves people’s lives. The United States now must build on the importance progress made in recent years.”

It has been five years since the last climate summit in Copenhagen and the next summit will take place next year in Paris. Obama noted that scientists have learned a great deal more about climate change in the past few years and that they will continue to learn more. He also stressed that climate change is happening and action will mean survival.

“As the President made clear, we don’t have the luxury to act as though climate change isn’t happening,” continued Morgan. “For the most vulnerable communities, taking action now is a matter of survival. The good news is that we have the technology and techniques in hand to both shift to the low carbon economy and build resilience to climate impacts. President Obama’s announcement today is a key step in putting those tools to use. Better and more information about climate impacts is one of our most powerful tools to combat climate change. The President has signaled his commitment to ensure everyone around the world has access to the data they need to anticipate and protect themselves from the consequences of global warming.”

Read More

$8B Green Energy Plan Proposed for LA

Pathfinder Renewable Wind Energy, Magnum Energy, Dresser-Rand and Duke-American Transmission have jointly proposed a $8 billion green energy plan that would bring large amounts of renewable power to the Los Angeles, California area by 2023. The companies will formerly submit their proposal to the Southern California Public Power Authority by early 2015.

If accepted, the project would require construction of one of America’s largest wind farms in Wyoming, one of the world’s biggest energy storage facilities in Utah, and a new 525-mile electric transmission line connecting the two sites. The proposed project would generate more than twice the amount of electricity produced by the giant 1930s-era hydroelectric dam in Nevada – 9.2 million megawatt-hours per year vs. 3.9 million megawatt-hours.

“This project would be the 21st century’s Hoover Dam – a landmark of the clean energy revolution,” said Jeff Meyer, managing partner of Pathfinder Renewable Wind Energy.

A key component of the project is a massive underground energy storage facility that would yield 1,200 megawatts of electricity, equivalent to the output of a large nuclear power plant and enough to serve an estimated 1.2 million L.A.-area homes. According to the proposal, the underground energy storage facility would help solve one of renewable energy’s biggest challenges – its intermittency. Wind farms produce no electricity when there’s no wind; solar farms produce no electricity when there’s no sun.

Linking the wind farm to the energy storage facility would enable the wind farm to function largely like a traditional coal, nuclear or natural gas power plant – capable of reliably delivering large amounts of electricity whenever needed, based on customer demand.

The energy storage facility also would reduce the need for L.A.-area utilities to build expensive backup power plants and power lines to serve customers on days when there’s no wind, at night when there’s no sunlight, and during other periods when traditional wind and solar farms are unable to produce electricity.

According to the plan, Duke-American Transmission would build a $2.6-billion, 525-mile, high-voltage electric transmission line that would transport the Wyoming wind farm’s electricity to the Utah energy storage facility. From there, using an existing 490-mile transmission line – traversing Utah, Nevada and California- electricity would be transmitted from the Utah energy storage facility to the Los Angeles area.