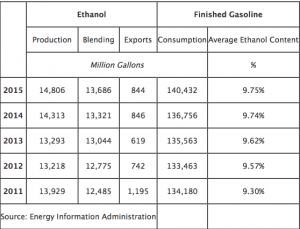

New records were set in 2015 for U.S. ethanol production and blending according to data from the Energy Information Administration (EIA). Last year ethanol production hit a record high of 14.81 billion gallons while refiners and blenders integrated a record 13.69 billion gallons into the U.S. gasoline supply. The industry’s monthly average output in December 2015 also crested the 1 million-barrel-per-day mark for the first time in history.

Data from the U.S. Environmental Protection Agency (EPA) shows that output levels of corn ethanol were primarily responsible for a record generation of 14.83 billion Renewable Identification Numbers (RINs) used by obligated parties to track compliance under the Renewable Fuel Standard (RFS).

Data from the U.S. Environmental Protection Agency (EPA) shows that output levels of corn ethanol were primarily responsible for a record generation of 14.83 billion Renewable Identification Numbers (RINs) used by obligated parties to track compliance under the Renewable Fuel Standard (RFS).

Renewable Fuels Association (RFA) President and CEO Bob Dinneen said that while the numbers are impressive, the American ethanol industry is prepared to do more. Unfortunately, added Dinneen, mismanagement of the RFS program and the oil industry’s intransigence to adopt higher-level ethanol blends like E15 kept the ethanol industry from realizing its full potential. EPA set the 2015 blending obligation for renewable fuel at just 14.05 billion gallons, rather than the 15 billion gallon level established by Congress – an act that is being challenged in federal court.

“The U.S. ethanol industry had an incredible year in 2015, but the failure of the White House and EPA to enforce the RFS as designed by Congress means our nation missed a huge opportunity to provide consumers with even larger volumes of domestically produced, low-carbon, high-octane biofuels,” said Dinneen. “There is no doubt that the ethanol industry could have produced even more renewable fuel if the Administration had stood firm on implementation of the statutory RFS volumes, rather than caving to the oil industry’s ‘blend wall’ narrative.”Read More