The announcement this week out of Beijing that China’s Ministry of Commerce has launched an anti-dumping probe into the ethanol co-product distillers dried grains (DDGS) from the US came as a surprise to the U.S. Grains Council (USGC).

“The U.S. Grains Council has a 25 year history of market development and capacity building programs in China and values the U.S./China market and trade relationship,” said USGC President and CEO Tom Dorr in a statement today. “China’s investigation of U.S. DDGS imports is surprising and could be disruptive to trade. China’s unusual market and supply volatility over the last two years has resulted in new global trade flows. As trade flows change, it should perhaps not be surprising there would be an adjustment period in response to unprecedented demand.”

It was only a few weeks ago that U.S. corn growers were in China on a USGC-sponsored trade mission to promote both corn and DDGS for livestock feed in that country. According to a post about the mission on the USGC blog The Grain Board, “Many of the feed companies that the delegation met with are increasing their DDGS use in their livestock feed rations. They stated they would continue to import, dependent on price. DDGS is easily imported into China, yet it is a feed ingredient that requires a “per plant registration” which is difficult to deal with at the port.”

It was only a few weeks ago that U.S. corn growers were in China on a USGC-sponsored trade mission to promote both corn and DDGS for livestock feed in that country. According to a post about the mission on the USGC blog The Grain Board, “Many of the feed companies that the delegation met with are increasing their DDGS use in their livestock feed rations. They stated they would continue to import, dependent on price. DDGS is easily imported into China, yet it is a feed ingredient that requires a “per plant registration” which is difficult to deal with at the port.”

China is the number one market for DDGS and is expected to import nearly three million metric tons this year, up more than 500 percent compared to a year ago. It is estimated that China produces about 3.5 million tons of DDGS domestically each year.

According to a statement from the Chinese Ministry, they initially plan to look for any evidence of dumping of DDGS, both with and without solubles, between July 2009 and June 2010, but may go back as far as 2007. The investigation is expected to take 12 to 18 months to complete.

“Xylose is a wood sugar, a five-carbon sugar that is very abundant in lignocellulosic biomass but not in our food,” said Yong-Su Jin, a professor of food science and human nutrition at Illinois and a principal investigator on the study. “Most yeast cannot ferment xylose.” A big part of the problem with yeasts altered to take up xylose is that they will suck up all the glucose in a mixture before they will touch the xylose, Jin said. A glucose transporter on the surface of the yeast prefers to bind to glucose. “It’s like giving meat and broccoli to my kids,” he said. “They usually eat the meat first and the broccoli later.”

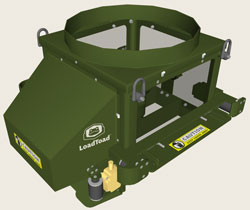

“Xylose is a wood sugar, a five-carbon sugar that is very abundant in lignocellulosic biomass but not in our food,” said Yong-Su Jin, a professor of food science and human nutrition at Illinois and a principal investigator on the study. “Most yeast cannot ferment xylose.” A big part of the problem with yeasts altered to take up xylose is that they will suck up all the glucose in a mixture before they will touch the xylose, Jin said. A glucose transporter on the surface of the yeast prefers to bind to glucose. “It’s like giving meat and broccoli to my kids,” he said. “They usually eat the meat first and the broccoli later.” It’s called the Load Toad™ and it was designed to allow rail cars to be packed more densely by forcing DDGS to the sides of the rail car, a process that is usually done by hand with a shovel. By distributing the DDGS load more evenly and efficiently, POET plants have been able to pack 3%-5% more DDGS into each car.

It’s called the Load Toad™ and it was designed to allow rail cars to be packed more densely by forcing DDGS to the sides of the rail car, a process that is usually done by hand with a shovel. By distributing the DDGS load more evenly and efficiently, POET plants have been able to pack 3%-5% more DDGS into each car.

Scaled up, VandenBrekel envisions a host of 1,000-to-20,000-acre farms across the Southeast where algal fuel is grown, processed and used locally, from community gas stations to diesel fleets such as school buses. Success, he says, would create no less than a “rebirth of American agriculture.”

Scaled up, VandenBrekel envisions a host of 1,000-to-20,000-acre farms across the Southeast where algal fuel is grown, processed and used locally, from community gas stations to diesel fleets such as school buses. Success, he says, would create no less than a “rebirth of American agriculture.”