The Provo Office of the Bureau of Reclamation completed a ground mount, 96 panel solar energy system in a former unused grassy area on the south side of their building located at 302 East 1860 South in Provo this summer. Local company, TRA Snow and Sun, Inc. of American Fork, Utah, manufacturer of solar mounting systems and snow retention systems, supplied the ground mounting for the panels and Intermountain Wind and Solar was the integrator.

The Provo Office of the Bureau of Reclamation completed a ground mount, 96 panel solar energy system in a former unused grassy area on the south side of their building located at 302 East 1860 South in Provo this summer. Local company, TRA Snow and Sun, Inc. of American Fork, Utah, manufacturer of solar mounting systems and snow retention systems, supplied the ground mounting for the panels and Intermountain Wind and Solar was the integrator.- Solectria Renewables, LLC, a leading U.S. PV inverter manufacturer, announced today that it will supply 69 SGI 500XTM’s to Entropy Solar Integrators for seven projects in North Carolina. These projects are part of a portfolio being built by Entropy Solar Integrators and financed through affiliates of Entropy Investment Management.

- Starwood Energy Group Global, LLC, a leading private investment firm focused on energy infrastructure, has announced that an affiliate has completed agreements to finance and construct its second wind farm, a 165 Megawatt (MW) project 45 miles south of Lubbock, Texas. The Stephens Ranch II project, which represents the second of two phases that will total 377 MW, will use GE 1.7-100 turbines and be built by Wanzek Construction, with completion scheduled for mid-2015.

- MENA Clean Energy Forum will be take place in Dubai on December 9, 2014. The MENA Clean Energy Forum will bring together stakeholders interested in investing, financing, developing and operating clean energy projects in the regions. The summit will provide a platform for networking, knowledge transfer and new business development with decision makers within the clean energy Industry.

Biogas Opportunities Roadmap Published

The U.S. Departments of Agriculture (USDA) and Energy (DOE) along with the Environmental Protection Agency (EPA) have published a new report that outlines new federal initiatives to support growth in the private biogas/waste-to-energy sector. The Biogas Opportunities Roadmap concluded that developing a viable biogas industry in the U.S. can boost the economy as well as provide a reliable, distributed source of renewable energy while reducing greenhouse gas emissions.

The report found that today there are 2,000 biogas sites operating and with opportunity for another 11,000 additional biogas systems to covert waste to energy and co-products. However, to make way for these additional biogas systems, there must be support from federal agencies, significantly more investment, increased research and development and expanded markets for biogas, according to the report.

The report found that today there are 2,000 biogas sites operating and with opportunity for another 11,000 additional biogas systems to covert waste to energy and co-products. However, to make way for these additional biogas systems, there must be support from federal agencies, significantly more investment, increased research and development and expanded markets for biogas, according to the report.

In the Biogas Opportunities Roadmap, the federal agencies identify programs that will promote biogas utilization and help the private sector take advantage of the full potential of biogas system without legislation. These programs include:

- Using existing agency programs to leverage over $10 million in research funding.

- Fostering investments in biogas systems including reviewing government procurement programs for products of biogas systems.

- Strengthening markets for biogas systems and system products including by modernizing existing Federal incentives.

- Improving communication and coordination by establishing a Biogas Opportunities Roadmap Working Group that will include participation from DOE and EPA, as well as the dairy and biogas industries.

“The potential for biogas to increase renewable energy production, reduce landfill waste, benefit the environment, and spur economic growth in the U.S. is significant. We are very pleased to see the U.S. government publish a report that outlines these benefits and opportunities,” said Shlomi Palas, CEO of Blue Sphere Corporation, a company specializing in biogas technology. “Bluesphere is actively working in several U.S. states to develop biogas facilities. We have brought our global expertise in building and operating waste-to-energy facilities to the U.S. market and we’re finding very strong interest in the value proposition we have to offer. We are eager to expand our operations in the U.S. in conjunction with some major partners and to capitalize on biogas opportunities.”

Bluesphere has begun design and engineering work, and is scheduled to break ground in 2014 on a 5.2 MW waste-to-energy anaerobic digester in Charlotte, North Carolina. The company is also developing in a 3.2 MW waste-to-energy project in Rhode Island and has a Memorandum of Understanding to develop a 5.2 MW waste-to-energy project in Massachusetts.

Empower Energies Completes Mass Solar Project

Empower Engeries has completed and commissioned a 3.3 MWDC solar project in Shirley, Massachusetts. The ground mounted installation features 13,047 6.5′ by 3′ PV solar panels and is located on 27 acres of Shirley Water District land. The project was co-developed with Washington, DC-based EPG Solar. It will deliver over 4.9 million kWh of electricity annually to the contiguous Devens Utilities Department.

Jim Moore of the Devens Utilities Department said that Mass Development was originally looking to add renewable energy into their portfolio with facilities built behind their meter, but ultimately opened the bidding up to power supply coming in from outside Devens, ‘if someone could work out the details’.

Jim Moore of the Devens Utilities Department said that Mass Development was originally looking to add renewable energy into their portfolio with facilities built behind their meter, but ultimately opened the bidding up to power supply coming in from outside Devens, ‘if someone could work out the details’.

Empower Energies Manager of Business Development Micah Stanley credited the ingenuity of Robert Babcock, a Managing Partner with EPG Solar, and his team, for initiating the project. “His inventiveness enabled us, essentially, to put two separate and distinct projects together, and then enabled us to cross utility grid lines,” Stanley said.

“From the beginning, this project has been a model of perseverance and creativity for all of the parties involved,” Babcock added. “We worked diligently in cooperation with all of the constituencies – the Town of Shirley Energy Committee, the Water District, and the Devens Utilities Department – to best represent the interests of the people they serve.”

Len Jornlin, CEO of Empower Energies, added “It is exciting and humbling to ‘flip the switch’ after so many moving parts have come together. Projects like this one are characterized by a complex set of transactions, and the collaboration of so many stakeholders. We were thrilled to serve as the hub of all this effort. It enabled us to connect the dots, and help our co-developer, EPG Solar, to get the project over the finish line for Green States Energy and the Town of Shirley.”

Empower Energies and EPG Solar selected Green States Energy, Inc., to be the investor/owner of the solar system.

MIT Researchers Convert Lead to Solar Power

Researchers at MIT are recycling materials from discarded car batteries into long-lasting solar panels that provide emissions free power while keep lead out of landfills. The system was described in the journal Energy and Environmental Science and was co-authored by Angela M. Belcher and Paula T. Hammon along with graduate student Po-Yen Chen, and three others.

The system is based on a recent development in solar cells that makes use of a compound called perovskite — specifically, organolead halide perovskite — a technology that has rapidly progressed from initial experiments to a point where its efficiency is nearly competitive with that of other types of solar cells.

“It went from initial demonstrations to good efficiency in less than two years,” said Belcher, the W.M. Keck Professor of Energy at MIT. Already, perovskite-based photovoltaic cells have achieved power-conversion efficiency of more than 19 percent, which is close to that of many commercial silicon-based solar cells.

Initial descriptions of the perovskite technology identified its use of lead, whose production from raw ores can produce toxic residues, as a drawback. However by using recycled lead from old car batteries, the manufacturing process can instead be used to divert toxic material from landfills and reuse it in photovoltaic panels that could go on producing power for decades. In addition, because the perovskite photovoltaic material takes the form of a thin film just half a micrometer thick, the team’s analysis shows that the lead from a single car battery could produce enough solar panels to provide power for 30 households.

As an added advantage, the production of perovskite solar cells is a relatively simple and benign process. “It has the advantage of being a low-temperature process, and the number of steps is reduced” compared with the manufacture of conventional solar cells, Belcher explained.

Those factors will help to make it “easy to get to large scale cheaply,” added.Read More

Albion Community Power Funds Biogas Project

![]() Albion Community Power (ACP) has funded the development of a small scale landfill gas engine in Docking, Norfolk (UK). The project will be developed in conjunction with ACP’s biogas partner AlphaGen Renewables who will oversee the installation and operation of a 50kW microgeneration landfill gas engine. The project will generate power from the landfill gas resource at the site under a 20 year agreement with Norfolk County Council. The Docking projects represents the first project with AlphaGen Renewables and the first Biogas project in the ACP portfolio.

Albion Community Power (ACP) has funded the development of a small scale landfill gas engine in Docking, Norfolk (UK). The project will be developed in conjunction with ACP’s biogas partner AlphaGen Renewables who will oversee the installation and operation of a 50kW microgeneration landfill gas engine. The project will generate power from the landfill gas resource at the site under a 20 year agreement with Norfolk County Council. The Docking projects represents the first project with AlphaGen Renewables and the first Biogas project in the ACP portfolio.

Richard Tipping, Chairman of AlphaGen Renewables said, “We are delighted to be partnering with ACP on this project, which is set to deliver strong returns. Renewables such as biogas are playing a growing role in the UK’s energy production.”

ACP undertakes projects in biogas as well as projects incorporating wind, hydro and solar energy. The company is looking to build a portfolio of similar, high yielding, landfill projects going forward.

David Gudgin, Head of at Renewables at Albion Ventures added, “Biogas is an increasingly popular area of renewable energy and we are looking forward to working with AlphaGen both on this project and others in the future.”

Ethanol Safety Seminar Heads to Mass

There will be a free Ethanol Safety Seminar held on August 26-17, 2014 in Westfield, Massachusetts. Co-hosted by the Renewable Fuels Association (RFA) and Fore River Transportation Corporation there will be a session from 9:00 am to 2:00 pm on Aug. 26, followed by a 10:00 am to 3:00 pm session on Aug. 27. Certificates will be awarded to attendees at the completion of the course, although interested participants should note that registration is limited. This seminar is the last to be funded this season by a Federal Railroad Administration grant through TRANSCAER.

“I’m excited. The RFA seminars offer both rail and emergency response professionals a venue to meet and plan for future events together,” said Paul Ruscio, general manager at Fore River Transportation Corp. “Rail has proven to be a safe and efficient mode of transportation for renewable fuels in the States. Being prepared for potential rail incidents by engaging responders makes good sense for us and our communities. The dialogue that ensues from these seminars creates educated teams that have the means and know-how to handle potential incidents. In my experience, a little preparation and coordination before a team faces a task usually proves beneficial.”

“I’m excited. The RFA seminars offer both rail and emergency response professionals a venue to meet and plan for future events together,” said Paul Ruscio, general manager at Fore River Transportation Corp. “Rail has proven to be a safe and efficient mode of transportation for renewable fuels in the States. Being prepared for potential rail incidents by engaging responders makes good sense for us and our communities. The dialogue that ensues from these seminars creates educated teams that have the means and know-how to handle potential incidents. In my experience, a little preparation and coordination before a team faces a task usually proves beneficial.”

The Ethanol Safety Seminar was developed to give first responders, emergency management agencies, and safety personnel an in-depth look at proper training techniques needed when responding to an ethanol-related emergency. A majority of this training is based on the “Training Guide to Ethanol Emergency Response,” a training package created by the Ethanol Emergency Response Coalition (EERC) that has been distributed throughout the United States and to several countries worldwide.

The course focuses on numerous important areas of ethanol safety including an introduction to ethanol and ethanol-blended fuels, chemical and physical characteristics of ethanol and hydrocarbon fuels, transportation and transfer of ethanol-blended fuels, storage and dispensing locations, firefighting foam principles and ethanol-blended fuel, health and safety considerations for ethanol-blended fuel emergencies and tank farm and bulk storage fire incidents.

BioEnergy Bytes

Dessler Media has announced the launch of their nationwide television commercial campaign that is structured to provide solar companies around the nation with exclusive pre-qualified residential solar leads and pre-qualified in home appointments. The participating solar companies have a choice of either having Dessler’s call center set an in-home appointment after qualifying the caller or to set up a telephone appointment after qualifying the inbound lead.

Dessler Media has announced the launch of their nationwide television commercial campaign that is structured to provide solar companies around the nation with exclusive pre-qualified residential solar leads and pre-qualified in home appointments. The participating solar companies have a choice of either having Dessler’s call center set an in-home appointment after qualifying the caller or to set up a telephone appointment after qualifying the inbound lead.- Caltech’s Resnick Sustainability Institute has announced that nominations are open for the 2015 Resonate Awards. The awards are designed to bring attention to unheralded innovators with provocative ideas that contribute to long term sustainability. These include meeting the world’s energy needs sustainably, providing water and food for a growing world population, cleaning the environment, improving people’s access to the natural resources they need to live a productive life, and many others.

- Solar Power Mid-Atlantic, a new regional event highlighting the strong solar industry in New Jersey, Pennsylvania, Maryland and Delaware, will be taking place September 9-10, 2014 in Atlantic City, New Jersey. The event is presented by Solar Energy Industries Association (SEIA) and Solar Electric Power Association (SEPA). The two days of programming will offer in-depth sessions and keynotes on the challenges and opportunities in the Mid-Atlantic solar market, as well as exhibits and demonstrations from solar firms and networking events.

- Denver-based SunShare has it has contracted with Adams County to provide the regional government with clean, reliable energy from Community Solar Gardens. Adams County will be the first county in the nation to power its buildings with privately developed Community Solar energy. SunShare is one of the nation’s first Community Solar providers.

Oregon Clarifies Biodiesel Rules

The Oregon Department of Agriculture has clarified some of its rules about what needs to be sold as biodiesel. The agency says it sent notices to more than 400 retailers that they can’t market diesel with 6 to 20 percent biodiesel as “diesel.”

The Oregon Department of Agriculture has clarified some of its rules about what needs to be sold as biodiesel. The agency says it sent notices to more than 400 retailers that they can’t market diesel with 6 to 20 percent biodiesel as “diesel.”

“We have investigated a number of consumer complaints alleging that certain retail fuel establishments are advertising diesel on their street signs at a significant discount relative to the competition,” says Steve Harrington, ODA’s Weights and Measures Program Manager. “When the consumer pulls in to fill up, they find out they are getting B20 and not the normal B5 diesel. B20 does not meet the legal specification for diesel and may not be marketed as such.”

During the 2013 Oregon legislative session, HB 2435 was passed which exempts diesel fuel blended with a minimum of 20 percent biodiesel (B20), derived from used cooking oil, from the state highway excise tax on fuel, which is 30 cents per gallon.

In response, ODA has sent out a notice addressed to all gas stations having licensed dispensers, both retail and card lock, advising them of the legal requirements for advertising B20. Essentially, B20 is required to be clearly advertised both on the street signs and dispensers so that the consumer may make an informed buying decision. If the prominent markings on the dispenser indicate that the product is diesel, then the product must meet with the diesel specification or it will be ordered off sale by ODA until the product labeling is corrected.

The agency says the 30-cent price discount without the tax makes B20 especially attractive for consumers, but officials worry it doesn’t meet some vehicle manufacturers’ specifications.

Feds: Propane Inventories Growing Strong

Propane uses, especially Midwestern farmers, are hoping to avoid a repeat of last winter’s high prices, low inventories and logistical and infrastructure challenges that caused some real problems last year. The latest information from the U.S. Energy Information Administration shows that while inventories are below average, they’re above the numbers from a year ago and are trending upwards in the last few weeks.

While inventory levels in the Midwest remain below the five-year average, above-average builds over the past six weeks are an encouraging trend. Last year, propane inventories in the Midwest (PADD 2) for the week ending August 9 were 21.5 million barrels, 3.4 million barrels below the five-year average. This year, PADD 2 propane inventories for the week ending August 8 are 23.4 million barrels, 1.9 million barrels higher than last year, but still 1.6 million barrels below the five-year average. However, in each of the past six weeks, PADD 2 propane inventory builds have surpassed their five-year averages, leading to a steady improvement in stock levels relative to their historical norms…

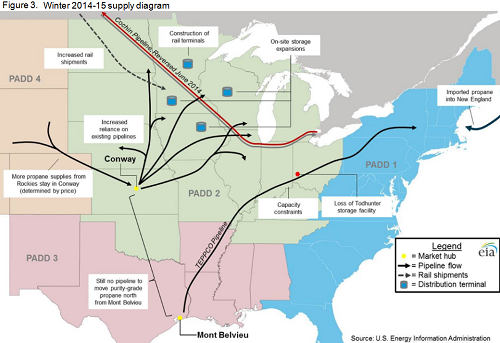

Last year, demand for propane used to dry crops in the Upper Midwest surged just before the start of winter and, as a result, propane inventories at distribution terminals were low before the start of winter heating season. In addition, distribution infrastructure challenges, pipeline maintenance, and rail delivery delays reduced supplies. This year, inventories are building earlier; however, there have been changes in infrastructure that could impact supply. The Cochin Pipeline, which delivered propane to the Upper Midwest from Canada, has been reversed and repurposed, removing a major source of propane supplies to the region.

Propane market participants have responded to the events of last winter and the Cochin reversal by diversifying supply sources. Instead of relying on propane delivered from Canada via Cochin, the region will now rely more on several existing pipelines to deliver propane north to the Upper Midwest from Conway. Additionally, propane rail capacity in the region has expanded via new propane rail terminals throughout the region. Finally, existing distribution terminals have added tanks, thus expanding storage capacity.

The report goes on to say that there will be continued infrastructure challenges for winter propane deliveries in the Midwest and the Northeast will have to rely on imports from Canada. In addition, an expected record corn harvest this year could put pressure on supplies again in the form of propane used for crop drying, but that will depend on fall weather patterns and harvest timing. How cold the winter is will as be the the most important and most difficult-to-predict factor influencing the propane supply-demand balance this winter.

DOE Funds EV Everywhere Grand Challenge

The U.S. Department of Energy (DOE) has announced more than $55 million for 31 new projects to accelerate research and development of critical vehicle technologies that will improve fuel efficiency and reduce costs. These new projects are aimed at meeting the goals and objectives of the President’s EV Everywhere Grand Challenge, as well as improvements in other vehicle technologies such as powertrains, fuel, tires and auxiliary systems.

Launched in 2012, the goal of the EV Everywhere Grand Challenge is by 2022 to make the U.S. automotive industry the first to produce plug-in electric vehicles (PEVs) that are as affordable and convenient as today’s gasoline-powered vehicles. According to the DOE, in just the last several years, significant cost reductions and improvements in vehicle  performance have had a dramatic impact on the U.S. automotive market. PEV sales continue to grow – sales in the first six months of 2014 were over 30 percent higher than the same period in 2013 – and the cost of battery technology has come down by over 60 percent since 2009.

performance have had a dramatic impact on the U.S. automotive market. PEV sales continue to grow – sales in the first six months of 2014 were over 30 percent higher than the same period in 2013 – and the cost of battery technology has come down by over 60 percent since 2009.

“Investments in the next generation of vehicle technologies will both strengthen our economy and lead to a more fuel efficient, clean energy future,” said Secretary Ernest Moniz. “Improving vehicle efficiency is instrumental to establishing a 21st century transportation sector that creates jobs as well as protects future generations from harmful carbon emissions.”

Through the Advanced Vehicle Power Technology Alliance with the DOE, the Department of the Army is contributing an additional $3.7 million in co-funding to support projects focused on beyond lithium ion battery technologies and reducing friction and wear in the powertrain. The Army will also test and evaluate fuel-efficient tires resulting from projects at its facilities in Warren, Michigan.

“Partnering with the Energy Department, we are accelerating the development and deployment of cutting-edge technologies that will strengthen our military, economy, and energy security,” said Dr. Paul Rogers, director the U.S. Army Tank Automotive Research, Development and Engineering Center.

The selections announced are under two major topic areas:

Critical Technologies to meet the EV Everywhere Grand Challenge: 19 projects are aimed at reducing the cost and improving the performance of key PEV components. This includes improving “beyond lithium ion technologies” that use higher energy storage materials, and developing and commercializing wide bandgap (WBG) semiconductors that offer significant advances in performance while reducing the price of vehicle power electronics. Other projects focus on advancing lightweight materials research to help electric vehicles increase their range and reduce battery needs, and developing advanced climate control technologies that reduce energy used for passenger comfort and increase the drive range of plug-in electric vehicles.

Fuel Efficiency Improvements in Passenger Vehicles and Commercial Trucks: 12 projects are aimed at improvements including developing and demonstrating dual-fuel/bi-fuel technologies to reduce petroleum usage, accelerating growth in high-efficiency, cost-competitive engine and powertrain systems for light-duty vehicles, and accelerating the introduction of advanced lubricants and coatings to increase the efficiency of vehicles on the road today as well as future vehicles.