The 30th annual Fuel Ethanol Workshop (FEW) has official kicked off with a record-breaking number of ethanol producers from around the world attending. The attendees represent more than 500 producers from 194 facilities representing more than 15 billion gallons of ethanol produced per year. Producers represent traditional and advanced ethanol facilities from the U.S., Canada, Argentina, Norway and Hungary.

Ethanol enthusiasts may note the significance of the 15 gallons of ethanol produced per year – the amount called for in the first-gen ethanol category of the Renewable Fuel Standard (RFS). A hot topic for the past few months and sure to be a hot topic during FEW, the Environmental Protection Agency (EPA) has yet to finalize the 2014 RFS rules and announced yesterday that they were delaying compliance for 2013 obligated parties until September 30, 2014.

Ethanol enthusiasts may note the significance of the 15 gallons of ethanol produced per year – the amount called for in the first-gen ethanol category of the Renewable Fuel Standard (RFS). A hot topic for the past few months and sure to be a hot topic during FEW, the Environmental Protection Agency (EPA) has yet to finalize the 2014 RFS rules and announced yesterday that they were delaying compliance for 2013 obligated parties until September 30, 2014.

The host of this year’s FEW is Indianapolis, Indiana. “The record level of ethanol producers at this year’s event has created an unprecedented opportunity for industry suppliers and supporters to network with ethanol producers and share their products or services,” said John Nelson, marketing director at BBI International. “We have 520 ethanol producers representing 194 ethanol production facilities already registered and we are expecting that number to grow.”

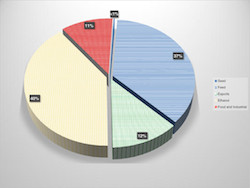

Drawing nearly 2,000 attendees, there will be at least 25 countries represented, 43 U.S. states represented and six Canadian provinces. During the course of the event, attendees will discuss issues categorized into four tracks:

- Track 1: Production and Operations

- Track 2: Leadership and Financial Management

- Track 3: Coproducts and Product Diversification

- Track 4: Cellulosic and Advanced Ethanol

energy.agwired.com will be bringing you coverage of FEW throughout the week.