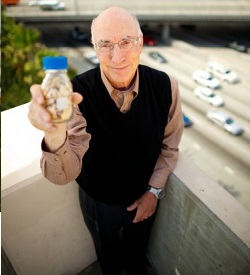

Fluctuations in the world oil market do impact ethanol energy demand and, in turn, production. During the National Ethanol Conference, John Kingston with McGraw Hill Financial Global Institute broke down how the petroleum markets have reacted and what that has meant for the ethanol industry.

Fluctuations in the world oil market do impact ethanol energy demand and, in turn, production. During the National Ethanol Conference, John Kingston with McGraw Hill Financial Global Institute broke down how the petroleum markets have reacted and what that has meant for the ethanol industry.

Kingston explained a variety of reports, such as the OPEC call and U.S. Energy Information Administration (EIA) information that has shown that U.S. oil production would drop, and now that is indeed being displayed not just on the theoretical level. That drop in oil production is also in response to an overall overage in the petroleum markets, which has pushed oil off its $100/barrel status down to nearly half of that now… with possibilities that it could drop to the $20s/barrel – an unthinkable drop from what was considered a “permanent high.” Part of what helped push those oil prices down has been a drop in gasoline demand. When oil is very cheap, it can make it much more difficult for ethanol producers to stay cost competitive. Adding in less gasoline for ethanol to be blended into, and those oil fluctuations are having an impact on ethanol. Kingston added that the government regulations on ethanol are adding to the issue.

“When you bring a government into a market, it tends not to operate as it would have otherwise. That volatility in the market [that has trickled down to ethanol producers] is quite substantial,” he said. “Ethanol will always be a a little more volatile than some of these petroleum-based products.”

Kingston said while the energy industries are creative in finding ways to stay profitable, they’ll just have to do it at much lower prices.

Listen to all of Kingston’s remarks here: John Kingston, McGraw Hill Financial Global Institute