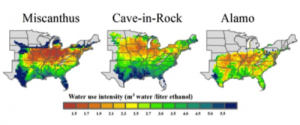

University of Illinois researchers have studied genetic markers of miscanthus to identify early developmental traits that will improve yield. According to the researchers, “this study begins to establish links between reproducible genetic markers and a number of key agronomic traits in Miscanthus sinensis.” The research paper was published in GCB Bioenergy, “Mapping the genome of Miscanthus sinensis for QTL associated with biomass productivity.”

Over a period of three years, researchers measured developmental and biomass traits over a period of three establishment years in the offspring of a cross between Miscanthus sinensis cultivars ‘Grosse Fontaine’ and ‘Undine.’ It can take three-four years for a miscanthus crop to have a reliable yield. Next, the team extracted DNA from the plants and examined the resulting single nucleotide polymorphisms, or SNPs, to develop a genetic map. The technique improves upon older types of genetic markers that were not as tightly linked to particular genes controlling important biomass traits.

Over a period of three years, researchers measured developmental and biomass traits over a period of three establishment years in the offspring of a cross between Miscanthus sinensis cultivars ‘Grosse Fontaine’ and ‘Undine.’ It can take three-four years for a miscanthus crop to have a reliable yield. Next, the team extracted DNA from the plants and examined the resulting single nucleotide polymorphisms, or SNPs, to develop a genetic map. The technique improves upon older types of genetic markers that were not as tightly linked to particular genes controlling important biomass traits.

“It represents one of the very first maps that was made and it’s also one of the first times we were able to map a number of genes associated with biomass productivity, and determine the locations of those genes in the Miscanthus genome,” said U of I geneticist Jack Juvik.

On a practical level, the researchers saw strong positive correlations between biomass yield and plant basal circumference, height, and tiller (stem) number, suggesting that plants that are able to grow taller and produce more tillers in the first few years may achieve higher yields in the long term. They also found negative correlations between flowering time and yield, with early flowering individuals producing less biomass. The researchers breeders could make use of that information to improve early selection of plants with enhanced biomass productivity to accelerate the breeding program.

“The advantage to marker-assisted breeding is that you can grow seedlings, collect DNA, and probe for a large suite of DNA markers that are linked to genes that confer the characteristics you want. That can save a lot of time, because you can identify potential phenotypes without having to wait 3-4 years to get a mature plant,” explained Juvik. “The value of this kind of system in Miscanthus is substantial in terms of breeding progress.”

In addition to saving time and providing breeders with specific traits to look for in high-yielding plants, the techniques used in the study and the initial results establish a jumping-off point for future work.

Juvik notes, “This is the starting point. We’ve continued this work and applied it to other populations and to other questions about breeding Miscanthus. This sets up the foundation for moving into a range of different applications.”

“We are excited to expand our digital presence to include these products that will be helpful for both domestic and international stakeholders,” said USGC Chairman Alan Tiemann, who farms in Nebraska. “The grains conversion app and the grains-in-all-forms portal are cutting-edge resources that contain information, trends and statistics that will help the global grain trade work and grow.”

“We are excited to expand our digital presence to include these products that will be helpful for both domestic and international stakeholders,” said USGC Chairman Alan Tiemann, who farms in Nebraska. “The grains conversion app and the grains-in-all-forms portal are cutting-edge resources that contain information, trends and statistics that will help the global grain trade work and grow.”