In a technological breakthrough for both renewable fuels and racing, cellulosic ethanol will be used for the first time in motor sports this year, paving the way for the biomass fuel to be used commercially.

In a technological breakthrough for both renewable fuels and racing, cellulosic ethanol will be used for the first time in motor sports this year, paving the way for the biomass fuel to be used commercially.

KL Process Design Group of South Dakota will supply the American Le Mans Series with cellulosic E85 racing ethanol for the 2008 season. The fuel, produced from waste wood, will be used for the first time during the season opener — Mobil 1 Twelve Hours of Sebring on March 15. Corvette Racing will be the first team to use the cellulosic-based flex-fuel ethanol in competition.

KL Process Design Group of South Dakota will supply the American Le Mans Series with cellulosic E85 racing ethanol for the 2008 season. The fuel, produced from waste wood, will be used for the first time during the season opener — Mobil 1 Twelve Hours of Sebring on March 15. Corvette Racing will be the first team to use the cellulosic-based flex-fuel ethanol in competition.

Scott Atherton, president and CEO of the American Le Mans Series. “The American Le Mans Series was recently recognized by the U.S. Department of Energy and the U.S. Environmental Protection Agency as the only motorsports entity to meet the criteria for ‘green racing’. Introducing cellulosic E85 racing ethanol to our series with one of our most noted championship teams does nothing but reinforce our commitment to be the global leader in green racing.”

Through the marketing partnership with the Ethanol Promotion and Information Council (EPIC), the American Le Mans Series will drive awareness of ethanol among consumers through its use of both E10 and E85 ethanol.

Through the marketing partnership with the Ethanol Promotion and Information Council (EPIC), the American Le Mans Series will drive awareness of ethanol among consumers through its use of both E10 and E85 ethanol.

“This is an exciting time for the ethanol industry,” said Reece Nanfito, senior director of marketing for EPIC. “Consumers want more choices at the pump, and although challenges remain, cellulosic ethanol is no longer a dream, but a reality.”

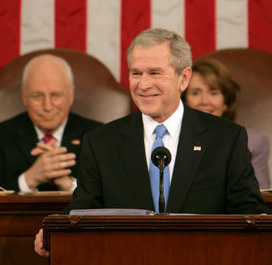

To build a future of energy security, we must trust in the creative genius of American researchers and entrepreneurs and empower them to pioneer a new generation of clean energy technology. Our security, our prosperity, and our environment all require reducing our dependence on oil. Last year, I asked you to pass legislation to reduce oil consumption over the next decade, and you responded. Together we should take the next steps: Let us fund new technologies that can generate coal power while capturing carbon emissions. Let us increase the use of renewable power and emissions-free nuclear power. Let us continue investing in advanced battery technology and renewable fuels to power the cars and trucks of the future. Let us create a new international clean technology fund, which will help developing nations like India and China make greater use of clean energy sources. And let us complete an international agreement that has the potential to slow, stop, and eventually reverse the growth of greenhouse gases.

To build a future of energy security, we must trust in the creative genius of American researchers and entrepreneurs and empower them to pioneer a new generation of clean energy technology. Our security, our prosperity, and our environment all require reducing our dependence on oil. Last year, I asked you to pass legislation to reduce oil consumption over the next decade, and you responded. Together we should take the next steps: Let us fund new technologies that can generate coal power while capturing carbon emissions. Let us increase the use of renewable power and emissions-free nuclear power. Let us continue investing in advanced battery technology and renewable fuels to power the cars and trucks of the future. Let us create a new international clean technology fund, which will help developing nations like India and China make greater use of clean energy sources. And let us complete an international agreement that has the potential to slow, stop, and eventually reverse the growth of greenhouse gases.  The U.S. branch of Dutch-based Corporate Express is converting its delivery trucks to biodiesel.

The U.S. branch of Dutch-based Corporate Express is converting its delivery trucks to biodiesel.

Fresh food giant Dole has a fresh idea about how it is fueling its fresh vegetable harvesters in the western United States: use biodiesel.

Fresh food giant Dole has a fresh idea about how it is fueling its fresh vegetable harvesters in the western United States: use biodiesel. A California company claims to have a new way to convert biomass into ethanol.

A California company claims to have a new way to convert biomass into ethanol. During

During  Legislation is being proposed in Illinois for ethanol blends between 10 and 85 percent.

Legislation is being proposed in Illinois for ethanol blends between 10 and 85 percent.  The goal of the new CFDC blog is to create an informative and ongoing public discussion about the numerous facts, myths, and highly emotional issues which will coattail the development and expansion of the nation’s increased RFS in the years to come.

The goal of the new CFDC blog is to create an informative and ongoing public discussion about the numerous facts, myths, and highly emotional issues which will coattail the development and expansion of the nation’s increased RFS in the years to come.