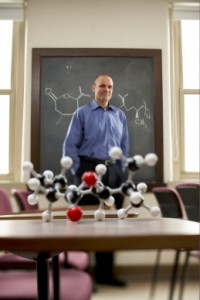

University of Minnesota researchers are developing degradable plastics from soybean oil. These bioplastics could become a replacement for those made with petroleum and natural gas. Marc Hillmyer, Distinguished McKnight University Professor of chemistry and Director of the Center for Sustainable Polymers, believes that to wean the country from all things fossil fuels, including chemicals and plastics, alternatives based on renewable resources must be developed.

One of the greatest challenges that must be overcome is the fact that while polylactides (PLA) are degradable polymers that can be used in a variety of products, they tend to soften at higher temperatures. This rules them out for extensive use in food and beverage packing applications. Enter Hillmyer. He and his team have developed new types of polyactide-based materials that could overcome this challenge.

One of the greatest challenges that must be overcome is the fact that while polylactides (PLA) are degradable polymers that can be used in a variety of products, they tend to soften at higher temperatures. This rules them out for extensive use in food and beverage packing applications. Enter Hillmyer. He and his team have developed new types of polyactide-based materials that could overcome this challenge.

Hillmyer believes this discovery could be used in a wide variety of applications that require high temperature stability and toughness. These include plastic bottles, microwave trays, cell phones and more. Hillmyer believes sustainable polymers are the “materials of tomorrow.”

The plasticizers developed by Hillmyer and his team including Dr. Dharma Kodali, are derived from soy oil. Kodali explained that the new plasticizers are synthesized in their lab and could be a viable replacement for petroleum-derived plasticizers. They are comparable in price and performance but are safer, says Kodali, because they are made from renewable resources and degrade readily if leaked into environment.

Current phthalates can leach from plastic and be harmful to the environment and people. Various studies have shown them to be carcinogenic and cause hormonal disruptions.

The soybean oil is chemically converted into new molecules that are useful for the production of things such as polyurethane foams (foam bedding, furniture, building materials). The soybean oil is renewable, degradable and cost competitive. Hillmyer said that so far, the plasticizers have demonstrated good general property profiles but they are not yet sure of the performance of foams at extreme temperatures. He also noted that while the rate of degradation varies on external conditions, on average, a cup made out of polylactide will degrade in an industrial compost environment over about two months.

The soybean oil is chemically converted into new molecules that are useful for the production of things such as polyurethane foams (foam bedding, furniture, building materials). The soybean oil is renewable, degradable and cost competitive. Hillmyer said that so far, the plasticizers have demonstrated good general property profiles but they are not yet sure of the performance of foams at extreme temperatures. He also noted that while the rate of degradation varies on external conditions, on average, a cup made out of polylactide will degrade in an industrial compost environment over about two months.

Hillmyer also said that many of these new materials are already cost competitive with petroleum based materials. However, the newer materials they are developing are in experimental stages and process optimization has not been performed. Therefore, the ultimate cost of the new experimental materials is undetermined at this time.

There is a big market for biopolymers. According to a USDA study conducted in 2008, bio-based polymers could account for nearly 33 percent of the total global market by 2025.

“The global polymer market is hundreds of billions of dollars,” said Hillmyer. “Our technologies could account for some fraction of this huge number.”

Marc Hillmyer’s research has taken place over the past four years, supported by grants from the USDA and Natureworks LLC. Dharma Kodali’s project is in its third year and is funded by United Soybean Board.