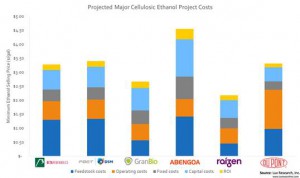

A new study from Lux Research finds innovation is still needed to make advanced biofuels competitive. The report cites six cellulosic ethanol facilities online and finds Raizen has the lowest projected minimum ethanol selling price of $2.17 per gallon. Abengoa’s $500 million Hugoton plant has the highest price of $4.55 with feedstock cost as the most critical variable. (It should be noted the study was conducted before the Hugoton plant was taken offline due to Abengoa’s financial troubles.)

“Improving feedstock aggregation and lowering feedstock cost is critical in cellulosic ethanol achieving cost parity, as feedstock cost can impact total cost by 40%,” said Yuan-Sheng Yu, Lux Research Analyst and lead author of the report titled, “Uncovering the Cost of Cellulosic Ethanol Production.”

and lowering feedstock cost is critical in cellulosic ethanol achieving cost parity, as feedstock cost can impact total cost by 40%,” said Yuan-Sheng Yu, Lux Research Analyst and lead author of the report titled, “Uncovering the Cost of Cellulosic Ethanol Production.”

Lux Research built a comprehensive cost model based on six cellulosic feedstocks and three pre-treatment technologies. Among their findings:

- Feedstock cost is a key differentiator. Two companies with the lowest projected minimum ethanol selling price – GranBio and Raizen – both utilize the cheapest cellulosic feedstocks. Sugarcane straw and sugarcane bagasse cost $40 and $38 per dry metric ton (MT), respectively, compared with corn stover ($90) used by Abengoa and POET-DSM and wheat straw ($75) used by Beta Renewables.

- Bigger is far from better. Abengoa’s Hugoton facility cost $500 million but despite getting economic credits for a 21 MW on-site generation unit, it is projected to have the highest projected selling price for ethanol of $4.55 per gallon.

- DuPont creates new economics. Even without electricity credits, DuPont has a projected selling price of $3.31 per gallon, similar to Beta Renewables and POET-DSM, at its 30 MGY plant. It uses improved feedstock aggregation processes, reducing corn stover from $90 per dry MT to $52 per day MT.

Yuan-Sheng Yu added, “Improvements in pre-treatment yield, enzyme performance and price, and fermentation efficiency potentially reduce costs by up to 16%.”