Build the plant and the biomass will come. Abengoa has announced that they have signed contracts with several biomass producers farming in and around Hugoton, Kansas, to provide 315,000 tons of cellulosic biomass by the end of 2011. Construction of the biorefinery is scheduled for this summer and expected to be fully operational sometime in 2013. Once in production, the plant will utilize 315,000 tons of biomass each year to produce 25 million gallons of cellulosic ethanol. The plant will also produce 25 megawatts of electricity, enough to power the ethanol conversion process. Once complete, the biorefinery will be Abengoa’s first second-generation facility and seventh bioethanol facility in the U.S., bringing the company’s total U.S. biofuel production to more than 400 million gallons.

Abengoa recognized early in the process that the company would need to ensure a steady stream of biomass in order for the plant to produce the maximum amount of biofuels each year. Therefore, they ensured the necessary amount of feedstocks would be available taking several issues into account.

Abengoa recognized early in the process that the company would need to ensure a steady stream of biomass in order for the plant to produce the maximum amount of biofuels each year. Therefore, they ensured the necessary amount of feedstocks would be available taking several issues into account.

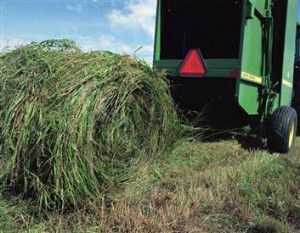

First, they needed to determine that adequate amounts of biomass were available within an economical transportation distance of the projected facility site. In addition, they needed to make sure that the biomass supply would be available during normal fluctuations of weather and different growing conditions. Second, they needed to ensure that the biomass could be harvested in a sustainable manner over the projected lifetime of the project. Third, they needed to work with the local producers to ensure that the biomass harvest would meet expectations in terms of quantity, quality and cost.

Abengoa will accept the bounty of the first biomass harvest this fall and will continue to accept biomass through the summer and fall of 2012. During the past three years, the company conducted various tests to determine best practices for harvesting the biomass in a sustainable manner that meets or exceeds Natural Resources Conservation Service (NRCS) minimum standards. These are aimed at preventing soil erosion and protecting soil health. Also during the testing phase, the company evaluated the best methods for storage, transportation and harvesting of the biomass.