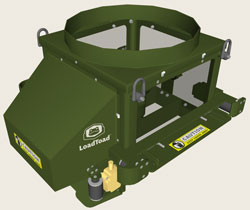

New equipment designed by POET has made loading distillers’ grains (DDGS) safer, faster, easier and ultimately more profitable for the company’s ethanol plants.

It’s called the Load Toad™ and it was designed to allow rail cars to be packed more densely by forcing DDGS to the sides of the rail car, a process that is usually done by hand with a shovel. By distributing the DDGS load more evenly and efficiently, POET plants have been able to pack 3%-5% more DDGS into each car.

It’s called the Load Toad™ and it was designed to allow rail cars to be packed more densely by forcing DDGS to the sides of the rail car, a process that is usually done by hand with a shovel. By distributing the DDGS load more evenly and efficiently, POET plants have been able to pack 3%-5% more DDGS into each car.

“The Load Toad not only allows us to put more DDGS in a railcar, which increases our production efficiency, but this device also allows the commodities team to more safely load a railcar,” said Dave Hudak, general manager at POET Biorefining – Alexandria (Ind.). “We no longer have to shovel any product nor stand on the top of the car to load it. The potential for a back injury has been eliminated.”

Commodities Assistant Ryan Schroeder from POET Biorefining – Leipsic in Ohio developed the first prototype of the Load Toad as a solution to a common loading problem that led to cone-shaped pileups in the rail cars. These pileups dramatically lowered efficiency in each rail car and created a great deal physical work for staff. “It felt good knowing that not just our plant would benefit, but the commodities people at all the POET plants would benefit,” Schroeder said. The Load Toad is currently being used at POET plants, but the company is exploring opportunities to market the technology to other ethanol producers in the future.

Here’s a video of the Load Toad in action from the POET website.