Researchers at the University of Wisconsin-Madison have reportedly developed a two-step method to convert the cellulose in raw biomass into biofuel.

The process, published in a recent Journal of the American Chemical Society issue, uses untreated, inedible biomass as the starting material.

The process, published in a recent Journal of the American Chemical Society issue, uses untreated, inedible biomass as the starting material.

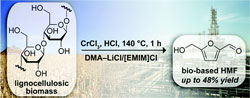

According to a story from the University of Wisconsin, the first step in the process is the conversion of cellulose into the “platform” chemical 5-hydroxymethylfurfural (HMF), from which a variety of valuable commodity chemicals can be made. “Other groups have demonstrated some of the individual steps involved in converting biomass to HMF, starting with glucose or fructose,” says Ronald Raines, a professor with appointments in the Department of Biochemistry and the Department of Chemistry. “What we did was show how to do the whole process in one step, starting with biomass itself.”

According to a story from the University of Wisconsin, the first step in the process is the conversion of cellulose into the “platform” chemical 5-hydroxymethylfurfural (HMF), from which a variety of valuable commodity chemicals can be made. “Other groups have demonstrated some of the individual steps involved in converting biomass to HMF, starting with glucose or fructose,” says Ronald Raines, a professor with appointments in the Department of Biochemistry and the Department of Chemistry. “What we did was show how to do the whole process in one step, starting with biomass itself.”

In the second step, Raines says they converted HMF into the promising biofuel 2,5-dimethylfuran (DMF). Taken together, the overall yield for this two-step biomass-to-biofuel process was 9 percent, meaning that 9 percent of the cellulose in their corn stover samples was ultimately converted into biofuel. Raines says DMF has the same energy content as gasoline, doesn’t mix with water and is compatible with the existing liquid transportation fuel infrastructure, having already been used as a gasoline additive.