Wednesday was the deadline to submit comments to the U.S. Treasury on the 45Z Clean Fuel Production Tax Credit and some members of Congress commented by introducing legislation that would extend the tax credit and limit it to renewable fuels made only from domestically sourced feedstocks.

Wednesday was the deadline to submit comments to the U.S. Treasury on the 45Z Clean Fuel Production Tax Credit and some members of Congress commented by introducing legislation that would extend the tax credit and limit it to renewable fuels made only from domestically sourced feedstocks.

Senators Roger Marshall (R-KS) and Amy Klobuchar (D-MN) reintroduced the bipartisan and bicameral Farmer First Fuel Incentives Act, as Representatives Tracey Mann (R-KS) and Marcy Kaptur (D-OH) introduced an identical bill in the House. The bill would extend the 45Z tax credit until December 31, 2034.

Additionally, this bill fixes the glaring flaw in 45Z that negatively impacts farmers wanting to sell feedstocks to the biodiesel and renewable diesel industry. If 45Z continues as-is, taxpayers are at risk of further subsidizing Chinese-used cooking oil and undermining the use of soy, canola, sorghum, and corn oil in renewable fuels.

Biofuels organizations that provided input to the Treasury agreed there needs to be an extension for the tax credit, which is already supposed to be in effect and is due to expire at the end of 2027.

“Thus, the three-year window intended by Congress is already closing and taxpayers do not yet have the clarity and certainty needed to make decisions about how best to position themselves to claim the 45Z tax credit,” wrote Renewable Fuels Association President and CEO Geoff Cooper in his detailed comments. “Given Treasury’s lengthy delay in proposing, finalizing, and promulgating 45Z regulations, we are encouraging policymakers to consider extending the duration of the 45Z tax credit.”

American Coalition for Ethanol (ACE) CEO Brian Jennings wrote, “Treasury should rapidly finalize 45Z guidance and include the technical guidelines for biofuel crops and carbon intensity calculator developed by USDA in the final 45Z rules, so ethanol producers and farmers can unlock new market opportunities,” and also called on Treasury to fully adopt USDA’s Feedstock Carbon Intensity Calculator (FD-CIC) and technical guidelines for biofuel feedstocks into 45Z.

Clean Fuels Alliance America urges Treasury to ensure a level playing field for American farmers, by eliminating penalties for speculative indirect effects assigned to U.S. crop feedstocks. Clean Fuels also urges Treasury to adhere to the legislative language indicating that co-processed fuels do not qualify for the credit.

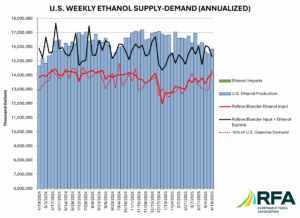

Per the Renewable Fuels Association’s analysis of EIA data, U.S. ethanol production for the week ending April 18, rose 2.1% to 1.03 million barrels per day (b/d), or 43.39 million gallons daily, up 8.3% from last year and 7.5% above the three-year average. While higher than the previous two weeks, the four-week average production dipped 0.5% to 1.03 million b/d, equating to 15.86 billion gallons annually.

Per the Renewable Fuels Association’s analysis of EIA data, U.S. ethanol production for the week ending April 18, rose 2.1% to 1.03 million barrels per day (b/d), or 43.39 million gallons daily, up 8.3% from last year and 7.5% above the three-year average. While higher than the previous two weeks, the four-week average production dipped 0.5% to 1.03 million b/d, equating to 15.86 billion gallons annually.