The 2025 International Fuel Ethanol Workshop & Expo (FEW) is being held June 9-11 at the CHI Health Center in Omaha, Nebraska. Now in its 41st year, the FEW keynote address will be given by Geoff Cooper, president & CEO of the Renewable Fuels Association.

The 2025 International Fuel Ethanol Workshop & Expo (FEW) is being held June 9-11 at the CHI Health Center in Omaha, Nebraska. Now in its 41st year, the FEW keynote address will be given by Geoff Cooper, president & CEO of the Renewable Fuels Association.

Following Geoff Cooper’s keynote address, a panel of industry association leaders will highlight key policy developments, challenges and industry goals. Participants include:

Moderator: Ben Rhodes, Executive Director, Nebraska Ethanol Board

• Brian Jennings, CEO, American Coalition for Ethanol

• Chris Bliley, Senior Vice President, Growth Energy

• Troy Bredenkamp, Senior Vice President, Government & Public Affairs, Renewable Fuels Association

The 2025 FEW promises three days of events, featuring a comprehensive program across four tracks:

Production and Operations: Biological Processes

Production and Operations: Mechanical Processes and Plant Control

Coproducts and Product Diversification

Leadership and Financial Management

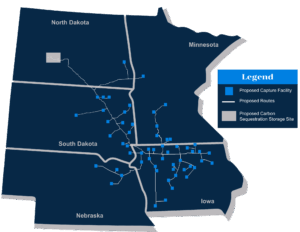

Attendees will also have the opportunity to engage with three co-located events, including the Carbon Capture & Storage Summit, the Sustainable Fuels Summit covering SAF, Renewable Diesel, and Biodiesel, and the Ethanol 101 session.