A new pretreatment could cut the costs of biofuels by 30 percent or more. This news release from the University of California, Riverside says researchers at the school have invented a novel pretreatment technology that could cut those production costs by dramatically reducing the amount of enzymes needed to breakdown the raw materials that form biofuels.

A new pretreatment could cut the costs of biofuels by 30 percent or more. This news release from the University of California, Riverside says researchers at the school have invented a novel pretreatment technology that could cut those production costs by dramatically reducing the amount of enzymes needed to breakdown the raw materials that form biofuels.

As partners in the BioEnergy Science Center (BESC), the team from the Bourns College of Engineering Department of Chemical and Environmental Engineering and Center for Environmental Research and Technology (CE-CERT) have shown that this new operation called Co-solvent Enhanced Lignocellulosic Fractionation (CELF) could eliminate about 90 percent of the enzymes needed for biological conversion of lignocellulosic biomass to fuels compared to prior practice. This development could mean reducing enzyme costs from about $1 per gallon of ethanol to about 10 cents or less.

The BioEnergy Science Center is a U.S. Department of Energy Bioenergy Research Center focused on enhancing science and technology to reduce the cost of biomass conversion through support by the Office of Biological and Environmental Research in the Department of Energy Office of Science..

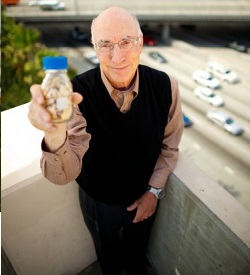

“As recent months have shown, petroleum prices are inherently unstable and will likely return to high prices soon as expensive sources are taken off line,” said Professor Charles Wyman, the Ford Motor Company Chair in Environmental Engineering at UC Riverside. “We have created a transformative technology that has the potential to make biofuels an economic sustainable alternative to petroleum-based fuels.”

Wyman’s findings were outlined in a just published paper, “Co-solvent Pretreatment Reduces Costly Enzyme Requirements for High Sugar and Ethanol Yields from Lignocellulosic Biomass,” in the journal ChemSusChem.