Earlier this week, I announced that I was kicking off a series on waste-to-energy and many people have already expressed comments and feedback on the subject. It is probably no coincidence that the hot button was the term incineration, aka combustion or burn. No one can see this term and not think pollution. While incinerators are still in use today, and will be the focus of Part 1 of this series, there are many new cutting edge waste-to-energy technologies that don’t use incineration and as the series progresses, we’ll be discussing these technologies.

Earlier this week, I announced that I was kicking off a series on waste-to-energy and many people have already expressed comments and feedback on the subject. It is probably no coincidence that the hot button was the term incineration, aka combustion or burn. No one can see this term and not think pollution. While incinerators are still in use today, and will be the focus of Part 1 of this series, there are many new cutting edge waste-to-energy technologies that don’t use incineration and as the series progresses, we’ll be discussing these technologies.

One of the first people I spoke with was Ted Michaels with the Energy Recovery Council based in Washington DC. The first question I asked him was how has the technology developed from the 1970s until now? Michaels began by explaining that the commercial waste-to-energy industry has existed since 1975 and today there are 86 waste-to-energy (WTE) facilities in 24 states that turn trash into energy through combustion.

The biggest differentiation of WTE facilities today, versus the WTE facilities of yesteryear, according to Michaels, are their ability to capture the energy and their utilization of emission control equipment. “America’s waste-to-energy facilities meet some of the most stringent environmental standards in the world and employ the most advanced emissions control equipment available,” said Michaels. “In fact, the US Environmental Protection Agency concluded in 2003 that America’s waste-to-energy plants have demonstrated “dramatic decreases” in air emissions, and produce electricity “with less environmental impact than almost any other source of electricity.”

According to Michaels, WTE achieves the reduction of greenhouse gas emissions (GHGs) through three separate mechanisms: 1) by generating electrical power or steam, waste-to-energy avoids carbon dioxide (CO2) emissions from fossil fuel based electrical generation; 2) the waste-to-energy combustion process effectively avoids all potential methane emissions from landfills thereby avoiding any potential release of methane in the future; and 3) the recovery of ferrous and nonferrous metals from MSW by waste-to-energy is more energy efficient than production from raw materials.

According to Michaels, WTE achieves the reduction of greenhouse gas emissions (GHGs) through three separate mechanisms: 1) by generating electrical power or steam, waste-to-energy avoids carbon dioxide (CO2) emissions from fossil fuel based electrical generation; 2) the waste-to-energy combustion process effectively avoids all potential methane emissions from landfills thereby avoiding any potential release of methane in the future; and 3) the recovery of ferrous and nonferrous metals from MSW by waste-to-energy is more energy efficient than production from raw materials.

Michaels explains that these three mechanisms provide a true accounting of the greenhouse gas emission reduction potential of waste-to-energy. “A lifecycle analysis, such as the EPA Municipal Solid Waste Decision Support Tool, is the most accurate method for understanding and quantifying the complete accounting of any MSW management option,” explained Michaels.

“A life cycle approach examines collection and transportation, material recovery facilities, transfer stations, composting, remanufacturing, landfills, and combustion. EPA studies show that waste-to-energy yields the best results—maximum energy with the least environmental impact (emissions of greenhouse gas, nitrogen oxide, fine particulate precursors, and others). In brief, waste-to-energy was demonstrated to be the best waste management option for both energy and environmental parameters and specifically for greenhouse gas emissions.

The next question, then, is the amount of opportunity in WTE. Is it worth the effort? Michaels said that the 86 WTE facilities in the U.S. have an electric generating capacity of 2700 megawatts through the management of 7 percent of the nation’s trash. More than 60 percent of our country’s trash currently goes to landfills so there are still a lot of opportunities to reduce landfill waste as communities continue to look for ways to reduce landfilling.

Let’s step back a minute and talk about how many homes can be powered by 7 percent our our trash. One megawatt can power 650 homes for one year so 2700 megawatts can power approximately 1,755,000 average U.S. homes for one year. In other words, 7 percent of our trash could power all the homes in North and South Dakota (est. combined populations in ’09 1.5 million people) with a little to spare.

While this seems pretty amazing, there are obviously challenges to developing the industry. Environmental policies are a major hurdle, as well as capital costs are high since WTE plants are, in essence, sophisticated power plants. Michaels said that in most communities, the WTE is one of their largest pieces of municipal infrastructure and when compared to the relative low cost of landfills, WTE requires planning and capital which many communities may find difficult to provide.

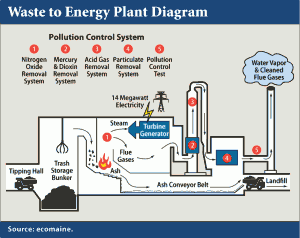

So let’s circle back to the technology. Here is a description of how it works from Michaels.

“The modern waste-to-energy plant is a technical marvel. It must burn a fuel ranging in size from a pea to a mattress. The fuel can be wet or dry, and it varies greatly in energy content. These plants burn the trash completely and scrub their exhaust with a number of sophisticated air pollution control systems to constantly comply with federal, state and local regulations. The first step in processing the trash is the receiving building. Most municipalities served by waste-to-energy plants have a recycling program, so the trash that is received at the plant has already had recyclables removed.

“The modern waste-to-energy plant is a technical marvel. It must burn a fuel ranging in size from a pea to a mattress. The fuel can be wet or dry, and it varies greatly in energy content. These plants burn the trash completely and scrub their exhaust with a number of sophisticated air pollution control systems to constantly comply with federal, state and local regulations. The first step in processing the trash is the receiving building. Most municipalities served by waste-to-energy plants have a recycling program, so the trash that is received at the plant has already had recyclables removed.

The trash is loaded into the furnaces. In the furnace, high temperature combustion completely destroys viruses, bacteria, rotting food and other organic compounds found in household garbage that could potentially impact human health. The heat from the burning garbage boils water flowing inside the boiler tubes and turns the water into steam.The steam can be used directly in a heating system or a factory. The steam is generally used to turn a turbine-generator to make electricity. After the combustion process, magnets and other mechanical devices pull metals from the ash for recycling.”

Okay. We know that no technology or fuel is perfect and WTE has its drawbacks. I asked Michaels, in his opinion, what these were. He answered that municipal solid waste is a difficult fuel to manage given the broad spectrum of materials that can be present in the trash in various quantities.

“The composition of the trash makes the energy efficiency less than that of other fuels, such as coal. However, trash is a fuel that is used for fuel rather than putting it in the ground, whereas coal is extracted from the Earth for the sole purpose of electric generation. In that respect, WTE is really solving two problems at once,” said Michaels.

In terms of the next generation of WTE, on the horizon (and in some cases already in action) is waste-to-energy through gasification, pyrolysis and plasma arc, all technolgies will will look at deeper in future installments of this series.