Loyola University Chicago is hosting a free Collegiate Biodiesel Workshop March 17-19, 2016. The workshop will bring together students, staff, faculty and members of the biodiesel community to discuss biodiesel efforts on college campuses as well as discuss best practices and lessons learned along with sharing resources and network. Click here for more information.

Loyola University Chicago is hosting a free Collegiate Biodiesel Workshop March 17-19, 2016. The workshop will bring together students, staff, faculty and members of the biodiesel community to discuss biodiesel efforts on college campuses as well as discuss best practices and lessons learned along with sharing resources and network. Click here for more information.- Gevo, Inc. has announced that it has entered into a license agreement and a joint development agreement with Porta Hnos S.A. to construct multiple isobutanol plants in Argentina using corn as a feedstock. The first plant is to be wholly owned by Porta and is anticipated to begin producing isobutanol in 2017. The plant is expected to have a production capacity of up to five million gallons of isobutanol per year. Based on projected isobutanol pricing, Gevo estimates that it could generate approximately $1 million in annual revenues once the plant is operational, through royalties, sales and marketing fees, and other revenue streams such as yeast sales.

- According to the U.S. EPA, a total of 1.74 million domestically produced D3 cellulosic biofuel RINs were generated in January, including 285,432 for ethanol, 1.29 million for renewable compressed natural gas and 161,044 for renewable liquefied natural gas.

- GE has announced that it has been selected by Belgian Eco Energy to build the largest greenfield, 100 percent biomass-fired power plant in the world. The supercritical plant, which will be powered by wood chips and agro residues, will generate approximately 215 MW of cleaner energy for the industry and nearby households reaching over 60 percent efficiency when operating in cogeneration mode.

U of Illinois Miscanthus Research Breakthrough

University of Illinois researchers have studied genetic markers of miscanthus to identify early developmental traits that will improve yield. According to the researchers, “this study begins to establish links between reproducible genetic markers and a number of key agronomic traits in Miscanthus sinensis.” The research paper was published in GCB Bioenergy, “Mapping the genome of Miscanthus sinensis for QTL associated with biomass productivity.”

Over a period of three years, researchers measured developmental and biomass traits over a period of three establishment years in the offspring of a cross between Miscanthus sinensis cultivars ‘Grosse Fontaine’ and ‘Undine.’ It can take three-four years for a miscanthus crop to have a reliable yield. Next, the team extracted DNA from the plants and examined the resulting single nucleotide polymorphisms, or SNPs, to develop a genetic map. The technique improves upon older types of genetic markers that were not as tightly linked to particular genes controlling important biomass traits.

Over a period of three years, researchers measured developmental and biomass traits over a period of three establishment years in the offspring of a cross between Miscanthus sinensis cultivars ‘Grosse Fontaine’ and ‘Undine.’ It can take three-four years for a miscanthus crop to have a reliable yield. Next, the team extracted DNA from the plants and examined the resulting single nucleotide polymorphisms, or SNPs, to develop a genetic map. The technique improves upon older types of genetic markers that were not as tightly linked to particular genes controlling important biomass traits.

“It represents one of the very first maps that was made and it’s also one of the first times we were able to map a number of genes associated with biomass productivity, and determine the locations of those genes in the Miscanthus genome,” said U of I geneticist Jack Juvik.

On a practical level, the researchers saw strong positive correlations between biomass yield and plant basal circumference, height, and tiller (stem) number, suggesting that plants that are able to grow taller and produce more tillers in the first few years may achieve higher yields in the long term. They also found negative correlations between flowering time and yield, with early flowering individuals producing less biomass. The researchers breeders could make use of that information to improve early selection of plants with enhanced biomass productivity to accelerate the breeding program.

“The advantage to marker-assisted breeding is that you can grow seedlings, collect DNA, and probe for a large suite of DNA markers that are linked to genes that confer the characteristics you want. That can save a lot of time, because you can identify potential phenotypes without having to wait 3-4 years to get a mature plant,” explained Juvik. “The value of this kind of system in Miscanthus is substantial in terms of breeding progress.”

In addition to saving time and providing breeders with specific traits to look for in high-yielding plants, the techniques used in the study and the initial results establish a jumping-off point for future work.

Juvik notes, “This is the starting point. We’ve continued this work and applied it to other populations and to other questions about breeding Miscanthus. This sets up the foundation for moving into a range of different applications.”

Platt’s & DOC Partner on Trade Opps for Ethanol

Platts has entered into a strategic agreement with the U.S. Department of Commerce’s (DOC) International Trade Administration (ITA) to provide fundamental forecasting data and in-depth analysis for ethanol producers looking for export opportunities.

Sarah Cottle, Platts global content director of agriculture, said of the announcement, “We’re pleased to be recognized by the U.S. Commerce Department’s International Trade Administration as a hallmark of quality, for our independent biofuels data and analytics. We look forward to working with the ITA to further the understanding and transparency in biofuels and agriculture markets and trade.”

According to Platts, its data and analysis will underpin the qualitative insights found in the ITA Renewable Fuels Top Markets Report that will be updated later in 2016 as part of the ITA agreement with Platts. The ITA provides U.S. businesses with tools and resources required to navigate the unique and rapidly growing biofuels marketplace through its Top Markets Report.

According to Platts, its data and analysis will underpin the qualitative insights found in the ITA Renewable Fuels Top Markets Report that will be updated later in 2016 as part of the ITA agreement with Platts. The ITA provides U.S. businesses with tools and resources required to navigate the unique and rapidly growing biofuels marketplace through its Top Markets Report.

“We’re pleased to welcome Platts as a partner in our efforts to strengthen the U.S. economy and support local jobs through expanding U.S. exports,” said Deputy Under Secretary for International Trade Ken Hyatt who was a speaking at the recent National Ethanol Conference in New Orleans. “With more than 95 percent of potential customers living outside U.S. borders, it’s imperative that American companies of all sizes consider the benefits of selling their products abroad. We believe this strategic agreement provides us with a unique opportunity to significantly enhance our analysis of potential exports for the U.S. biofuels industry and increase awareness of opportunities for U.S. exports globally.”

Research Looks Into Gas Prices

Your eyes do not deceive. I paid $1.40 per gallon for ethanol-blended fuel on Thursday, February 18, 2106 in Fairfield Glade, TN. Photo credit: Joanna Schroeder

As I pulled into a gas station in Fairfield Glade, Tennessee last week I couldn’t believe the price per gallon of fuel with ethanol. After nearly $5.00 per gallon of gas a few years ago in states such as California, I never thought I’d see prices drop below $2.00. But they have and continue to stay. While this is great news for drivers, Big Oil is not too happy about the billions of dollars they are losing with cheap oil. Crude Oil prices have fallen 23 percent in 2016, and 70 percent in the last 20 months – prices the world hasn’t seen in more than a decade.

According to AAA, the national average for gas this week is $1.70 per gallon – 55 cents less than this time last year. Interestingly, anti-biofuel advocates are using cheap oil as a call to end the Renewable Fuel Standard (#RFS) and stop blending corn-based ethanol into our nation’s fuel supply.

Professor Bruce Babcock of Iowa State University says oil companies are making “thoroughly outrageous claims” about what it would cost them, and you, to keep up with the plan to reduce greenhouse emissions. In his paper “Compliance Path and Impact of Ethanol Mandates on Retail Fuel Market in the Short Run,” co-authored by Sébastien Pouliot of Iowa State, Babcock found the impact on consumer prices is “close to zero.” This paper was recently selected to be published in the American Journal of Agricultural Economics.

“One of the reasons for writing this paper was to debunk the myths for justifications of getting rid of the RFS,” Babcock said. “This takes one of the justifications away.”

API Continues to Lambaste #RFS

The American Petroleum Institute (API) continues to lambaste the Renewable Fuel Standard (#RFS) as the energy policy draws criticism from all sides. Cited as the most effective energy policy ever enacted in the U.S. by supporters, API remains steadfast in its efforts to get the legislation repealed.

Shortly before a Senate committee oversight hearing on Wednesday, API’s Downstream Group Director Frank Macchiarola said during a press call, “Ahead of the hearing, we are reminding policy makers and the public that the oil and natural gas industry is stepping up our call for Congress to protect consumers from this harmful mandate. We continue to seek the repeal of or significant reforms to the RFS. Since the inception of the ethanol mandate a decade ago, the U.S. has undergone an energy transformation from a nation of energy dependence and scarcity to one of energy security and abundance. It is well past time to reform outdated energy policies to reflect the energy realities of today and tomorrow.”

Macchiarola added that API is hopeful support in Congress for repealing or modifying the RFS is growing. (Although if the current presidential race is any indication, this is in fact not true.)

Growth Energy responded to the remarks stating once again that the oil industry is spouting its “same old, disproven talking points about ethanol and the RFS”. The organization points to the fact that ethanol is the most tested fuel in American history; it’s a less expensive choice for consumers at the pump; and that NASCAR drivers have raced more than eight million miles on ethanol.

“Though this kind of rhetoric should be shocking, it no longer is,” said Tom Buis, co-chair of Growth Energy. “The oil industry has made a habit of repeatedly trotting out bogus studies for the single purpose of blocking competition and consumer choice to protect their profits. The fact is that rigorous testing and unbiased studies from the government and other industries have repeatedly demonstrated that ethanol and other biofuels are a less expensive, cleaner and better performing alternative to oil.”Read More

UNCTAD Report: Advanced Biofuels Here Now

Second generation biofuels made from non-food biomass are here right now according to a new report from UNCTAD. “Second-Generation Biofuel Markets: State of Play, Trade and Developing Country Perspectives,” finds these biofuels are a commercial reality in the context of advanced technologies, economic pressures and a political will to act on climate change. The report focuses on the role advanced biofuels can play in meeting global climate and energy goals and how to make the technology available in developing countries.

Second generation biofuels made from non-food biomass are here right now according to a new report from UNCTAD. “Second-Generation Biofuel Markets: State of Play, Trade and Developing Country Perspectives,” finds these biofuels are a commercial reality in the context of advanced technologies, economic pressures and a political will to act on climate change. The report focuses on the role advanced biofuels can play in meeting global climate and energy goals and how to make the technology available in developing countries.

With a specific focus on cellulosic ethanol, the report provides a wide-ranging review of the second-generation biofuels sector, maps selected cellulosic ethanol projects, and details recent policy developments from around the world. A key factor in decreasing costs for the industry has been process improvements that have allowed the market to expand, the report finds.

The United States has the largest installed capacity for cellulosic ethanol production and the greatest number of working second-generation biofuel facilities, the report found, followed respectively by the People’s Republic of China, Canada, the European Union (EU) and Brazil. As of 2015, there were no cellulosic ethanol projects on the African continent and in Latin America (excluding Brazil); however, progress has been made in bagasse-fired electricity co-generation and biomass cook stoves in these regions.

The report finds two main strategies have given traction to the growth of advanced biofuels. The first is a market-segmentation strategy in conventional/advanced cellulosic biofuels used in the U.S., and more recently in the EU with the adoption of limits for conventional biofuels, resulting in premium pricing. The second is the availability of national development bank loans that have reduced risk and promoted growth in the industry, especially in China and Brazil. Low interest rates and a venture-capital culture have also played a role in advancing the position of second-generation biofuels.

The report concludes with five suggestions for the responsible development of the second-generation global biofuels industry and is an update from a similar UNCTAD report published in 2014.

New BioJet Program Collaboration in Mexico

The Mexico’s Sector Fund for Energy Sustainability (SENER-CONACYT) is supporting a new biojet collaboration with Boeing, Aeromexico and Mexico’s Airports and Auxiliary Services (ASA). The goal of the program is to advance research and development of sustainable aviation biofuel in Mexico. The Mexican government and participating institutions will fund the effort for four years, aiming to develop a self-sustaining business model. Research will be conducted on biomass sourcing, fuel production, sustainability and lifecycle assessment, and aviation biofuel market development.

The project will be coordinated through the Mexican Bioenergy Innovation Center and will support Mexico’s aviation sector as well as help meet the country’s environmental and economic goals. Executives at Boeing, Aeromexico, ASA and the Potosinian Institute of Scientific and Technological Research (IPICYT) formalized the initiative at a ceremony in Mexico City. In total, there are 17 organizations throughout the world participating in the program.

The project will be coordinated through the Mexican Bioenergy Innovation Center and will support Mexico’s aviation sector as well as help meet the country’s environmental and economic goals. Executives at Boeing, Aeromexico, ASA and the Potosinian Institute of Scientific and Technological Research (IPICYT) formalized the initiative at a ceremony in Mexico City. In total, there are 17 organizations throughout the world participating in the program.

“To support customers and the aviation industry’s long-term growth, Boeing is proud to partner with Aeromexico and many key stakeholders to move Mexico’s sustainable aviation biofuel industry forward,” said Marc Allen, president, Boeing International. “Sustainable jet fuel will play a critical role in reducing aviation’s carbon emissions and will bring a new and innovative industry to Mexico.”

Aviation biofuel feedstocks will be sourced from Mexico and are expected to include jatropha, salt-tolerant Salicornia and sewage sludge. The initiative’s projects are expected to meet sustainability criteria established by the Roundtable on Sustainable Biomaterials.

“The success of these efforts would not be possible without the team work of Airports and Auxiliary Services (ASA) and our strategic partner Boeing,” said Sergio Allard, Chief of People & Industries Affairs Officer, Aeromexico. In Aeromexico, we recognize that conducting a sustainable operation is an everyday commitment. We are ready to assume the challenge and break the myth that you cannot be socially and environmentally responsible and competitive at the same time.”

Senate Holds #RFS Oversight Hearing

The U.S. Senate Committee on Environment and Public Works held an oversight hearing on the Renewable Fuel Standard (#RFS). The legislation has been under fire for several years and there are currently several lawsuits surrounding the program: the biofuels industry is suing because the required volumes (RVOs) for 2014, 2015 and 2016 are below what the legislation requires, and Big Oil is suing to reduce RVOs claiming there is not enough advanced gallons in the marketplace. In response to the hearing several ethanol associations stressed the importance of the benefits of the RFS to America.

“While we appreciate that the Administration improved the final Renewable Fuel Standard blending targets for 2016 compared to the purposed rule, regrettably, the methodology used to waive volumes for 2016 protects the old way of doing business by obstructing consumer access to cleaner fuels, stifling competition in the marketplace, and undermining innovation,” said Brian Jennings, the Executive Vice President of the American Coalition for Ethanol (ACE). “ACE members have made significant biofuel production advancements because of the RFS and we know that further innovation is within reach if federal policy continues to reward a competitive marketplace. ACE is strongly committed to ensuring consumers have access to high octane, low carbon, affordable blends of ethanol and we will explore all options at our disposal to achieve that goal with this Administration and the next.”

“While we appreciate that the Administration improved the final Renewable Fuel Standard blending targets for 2016 compared to the purposed rule, regrettably, the methodology used to waive volumes for 2016 protects the old way of doing business by obstructing consumer access to cleaner fuels, stifling competition in the marketplace, and undermining innovation,” said Brian Jennings, the Executive Vice President of the American Coalition for Ethanol (ACE). “ACE members have made significant biofuel production advancements because of the RFS and we know that further innovation is within reach if federal policy continues to reward a competitive marketplace. ACE is strongly committed to ensuring consumers have access to high octane, low carbon, affordable blends of ethanol and we will explore all options at our disposal to achieve that goal with this Administration and the next.”

Tom Buis, co-chair of Growth Energy stated, “Homegrown ethanol and the RFS are major wins for the American people. Biofuels, such as ethanol, are a 21st century fuel for 21st century vehicles. It is our only alternative to oil, and the RFS is the most effective policy in reducing cancer-causing chemicals and the toxic emissions that come from oil’s monopoly on our motor fuel supply. The RFS supports consumer choice, creates hundreds of thousands of jobs across America, strengthens our energy security and slashes climate change causing emissions.

Tom Buis, co-chair of Growth Energy stated, “Homegrown ethanol and the RFS are major wins for the American people. Biofuels, such as ethanol, are a 21st century fuel for 21st century vehicles. It is our only alternative to oil, and the RFS is the most effective policy in reducing cancer-causing chemicals and the toxic emissions that come from oil’s monopoly on our motor fuel supply. The RFS supports consumer choice, creates hundreds of thousands of jobs across America, strengthens our energy security and slashes climate change causing emissions.

“Policies like the RFS improve America’s climate, national security, rural economy and consumer choice. Repealing or changing the RFS would turn back the clock and undermine the progress we’ve made toward increasing America’s energy independence and cleaning our air and environment.”

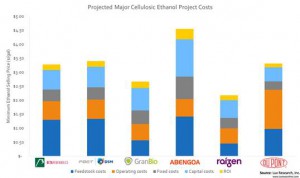

Cellulosic Ethanol Prices Hinges on Feedstocks

A new study from Lux Research finds innovation is still needed to make advanced biofuels competitive. The report cites six cellulosic ethanol facilities online and finds Raizen has the lowest projected minimum ethanol selling price of $2.17 per gallon. Abengoa’s $500 million Hugoton plant has the highest price of $4.55 with feedstock cost as the most critical variable. (It should be noted the study was conducted before the Hugoton plant was taken offline due to Abengoa’s financial troubles.)

“Improving feedstock aggregation and lowering feedstock cost is critical in cellulosic ethanol achieving cost parity, as feedstock cost can impact total cost by 40%,” said Yuan-Sheng Yu, Lux Research Analyst and lead author of the report titled, “Uncovering the Cost of Cellulosic Ethanol Production.”

and lowering feedstock cost is critical in cellulosic ethanol achieving cost parity, as feedstock cost can impact total cost by 40%,” said Yuan-Sheng Yu, Lux Research Analyst and lead author of the report titled, “Uncovering the Cost of Cellulosic Ethanol Production.”

Lux Research built a comprehensive cost model based on six cellulosic feedstocks and three pre-treatment technologies. Among their findings:

- Feedstock cost is a key differentiator. Two companies with the lowest projected minimum ethanol selling price – GranBio and Raizen – both utilize the cheapest cellulosic feedstocks. Sugarcane straw and sugarcane bagasse cost $40 and $38 per dry metric ton (MT), respectively, compared with corn stover ($90) used by Abengoa and POET-DSM and wheat straw ($75) used by Beta Renewables.

- Bigger is far from better. Abengoa’s Hugoton facility cost $500 million but despite getting economic credits for a 21 MW on-site generation unit, it is projected to have the highest projected selling price for ethanol of $4.55 per gallon.

- DuPont creates new economics. Even without electricity credits, DuPont has a projected selling price of $3.31 per gallon, similar to Beta Renewables and POET-DSM, at its 30 MGY plant. It uses improved feedstock aggregation processes, reducing corn stover from $90 per dry MT to $52 per day MT.

Yuan-Sheng Yu added, “Improvements in pre-treatment yield, enzyme performance and price, and fermentation efficiency potentially reduce costs by up to 16%.”

Do Farm Show Impact Farmers’ Buying Decisions?

Our latest ZimmPoll asked the question, “What is your favorite social media outlet for agriculture?”

Our latest ZimmPoll asked the question, “What is your favorite social media outlet for agriculture?”

It’s a tie! The two oldest forms of social media, Facebook and Twitter, rose to the top. When it comes to social media marketing in the agricultural field they ring tried and true. I still encourage people to step out of their comfort zones and see what other platforms have to offer. It is 2016 and social media is here to stay. Embrace it!

Here are the poll results:

- Facebook – 44%

- Twitter – 44%

- Instagram – 5%

- YouTube – 4%

- Pinterest – 3%

Our new ZimmPoll is now live and asks the question, How important are farm shows to farmers’ buying decisions?

Thousands of farmers and ranchers take in farm shows nationwide. Agribusinesses invest big marketing dollars to share their latest news and info to attendees. We are on the road year-round covering these shows and want to know if they impact buying decisions?