Researchers at the U.S. Department of Agriculture have developed a new strain of yeast that could cut the costs of cellulosic ethanol production. This Agricultural Research Service (ARS) news release says the work is being done at the agency’s National Center for Agricultural Utilization Research in Peoria, Ill.

Researchers at the U.S. Department of Agriculture have developed a new strain of yeast that could cut the costs of cellulosic ethanol production. This Agricultural Research Service (ARS) news release says the work is being done at the agency’s National Center for Agricultural Utilization Research in Peoria, Ill.

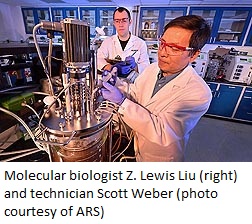

ARS molecular biologist Zonglin Lewis Liu and his colleagues determined that this yeast strain can break down and ferment the sugars in corn cobs left behind after the compound xylose—which is sometimes used for industrial activities—has been extracted. The new strain of yeast, Clavispora NRRL Y-50464 (Y-50464), can tolerate cob-derived compounds that interfere with yeast growth and fermentation rates.

It is able to grow rapidly at 98.6 °F, so it thrives at the higher temperatures needed to optimize simultaneous saccharification and fermentation (SSF) rates. SSF is a one-step process in cellulosic ethanol production that combines releasing and fermenting feedstock sugars…

The scientists added the enzymes cellulase and beta-glucosidase, which are often used to break down residues and extract sugars, and observed that Y-50464 reached its peak ethanol production rate of 25.7 grams per liter 5 days after the experiment began. But the yeast actually produced more ethanol, 26.6 grams per liter in 5 days, without the addition of beta-glucosidase.

Confirmation of beta-glucosidase in Y-50464 will eliminate the need to include the cost of that additional enzyme to the process.